According to a new study by DataHorizzon Research, the Chromium Carbide Overlay (CCO) Wear Plate Market is projected to grow at a CAGR of 8.3% from 2025 to 2033, driven by increasing demand for high-performance wear-resistant materials across mining, cement, steel, and construction industries. CCO wear plates, known for their superior hardness, abrasion resistance, and extended service life, are widely used in environments exposed to extreme mechanical wear. The market growth is primarily fueled by infrastructure modernization, rising mining exploration, and industrial automation that requires durable material solutions to minimize downtime and maintenance costs.

Market Size & Insights

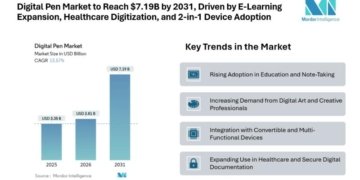

The chromium carbide overlay (CCO) wear plate market is valued at approximately USD 1.2 billion in 2024 and is anticipated to reach around USD 2.5 billion by 2033, reflecting a CAGR of 8.3% from 2025 to 2033, reflecting strong adoption across heavy-duty industries. These wear plates are typically manufactured by depositing chromium carbide overlay onto mild steel or other base metals through advanced welding processes. This combination offers exceptional protection against wear, impact, and heat, thereby extending the lifespan of industrial components such as chutes, hoppers, conveyors, and crusher liners.

Industries like mining, power generation, construction, and material handling are increasingly adopting CCO wear plates to reduce operational inefficiencies and maintenance costs. The growing shift toward performance-optimized materials, alongside advancements in surface engineering and metallurgical coating technologies, is expected to accelerate product adoption. Additionally, the rise in global infrastructure development and demand for renewable energy projects are further creating long-term opportunities for manufacturers.

The integration of digital fabrication techniques and laser cladding is also enabling the production of customized and precision-engineered wear plates, supporting higher efficiency and operational longevity in end-use sectors.

Get a free sample report: https://datahorizzonresearch.com/request-sample-pdf/chromium-carbide-overlay-cco-wear-plate-market-21708

Important Points

• Chromium carbide overlay wear plates offer superior resistance to abrasion, corrosion, and thermal damage.

• Increasing mining and cement production activities are major contributors to market demand.

• Advancements in welding and hardfacing technologies are improving wear plate performance and customization.

• Growing emphasis on reducing equipment downtime and maintenance cost drives adoption.

• The global expansion of construction and steel manufacturing industries supports market growth.

• Manufacturers are focusing on lightweight, high-strength composites for improved energy efficiency.

Key Factors Driving the Future Growth of the Chromium Carbide Overlay (CCO) Wear Plate Market

• Rising Industrial Infrastructure Investments: Growth in mining, cement, and power industries is directly boosting the demand for wear-resistant materials.

• Technological Advancements: Continuous innovations in overlay welding and surface hardening enhance product efficiency and longevity.

• Sustainability and Cost Efficiency: CCO plates help reduce equipment replacement frequency, lowering environmental and maintenance costs.

• Expanding Mining Activities: Increasing mineral extraction in Asia, Africa, and Latin America is fueling demand for wear plates in heavy machinery.

• Infrastructure Development: Global focus on transport, urban construction, and energy infrastructure drives steady material demand.

• Integration of Automation and Smart Manufacturing: Improved production consistency and reduced wastage promote scalability in manufacturing processes.

Top 10 Market Companies

• SSAB

• WALDUN

• Triton Wear Solutions

• Rhino Kart

• Enduraclad International

• Vidhi Engineers

• St. Lawrence Steel

• Wear Engineering Pvt. Ltd.

• JADCO Manufacturing

• CHROMEWELD

Market Segments

By Product Type:

o Standard CCO Wear Plates

o Complex Carbide Overlay (CCO) Wear Plates

By Application:

o Mining

o Construction

o Cement Manufacturing

o Steel Production

o Recycling

By End-Use Industry:

o Mining & Quarrying

o Construction

o Cement Industry

o Steel Mills

o Recycling Plants

By Region:

o North America

o Europe

o Asia-Pacific

o Latin America

o Middle East & Africa

Recent Developments

• Development of next-generation CCO plates with higher chromium and niobium content for extreme abrasion environments.

• Expansion of automated overlay welding facilities to improve surface consistency and production scalability.

• Strategic partnerships between steel manufacturers and surface engineering companies for enhanced supply chain integration.

• Introduction of lightweight wear plate variants for energy-efficient industrial applications.

• Investments in R&D to improve thermal resistance and hardness without compromising ductility.

• Adoption of AI-based quality control systems to enhance manufacturing precision and reduce production defects.

Regional Insights

Asia-Pacific dominates the global chromium carbide overlay wear plate market, accounting for a major share due to extensive mining operations, construction activities, and steel manufacturing in countries such as China, India, and Australia. North America follows closely, with strong demand from the mining, cement, and oil & gas industries. Europe shows steady growth, driven by automation and advancements in material technology. Meanwhile, Latin America and the Middle East & Africa are emerging as high-potential regions due to rising mining investments, infrastructure projects, and energy sector developments.

Market Outlook

The chromium carbide overlay (CCO) wear plate market is expected to experience consistent growth through 2033, supported by expanding industrialization and the rising need for high-durability materials. As industries seek to enhance productivity and minimize unplanned downtime, demand for CCO plates will continue to surge across heavy-duty equipment and machinery applications.

In the coming years, manufacturers will focus on sustainability, energy-efficient production, and improved recyclability to align with global environmental goals. The integration of digital fabrication technologies, advanced metallurgy, and automated welding systems will further optimize product quality and reduce production costs.

Moreover, the increased application of wear plates in renewable energy projects, such as biomass and wind energy, will open new growth opportunities. As industrial operations become more performance-driven, the CCO wear plate market will remain an essential enabler of reliability, efficiency, and long-term cost savings across multiple sectors.

Overall, the market’s future looks promising, powered by continuous innovation, material science advancements, and an expanding industrial base worldwide.

Contact:

Ajay N

Ph: +1-970-633-3460

Latest Reports:

Magnetic Closure Boxes Market: https://datahorizzonresearch.com/magnetic-closure-boxes-market-18575

Direct Injection High Pressure Pump Market: https://datahorizzonresearch.com/direct-injection-high-pressure-pump-market-19251

Single Mode Laser Diode Market: https://datahorizzonresearch.com/single-mode-laser-diode-market-19927

Passive Glider Market: https://datahorizzonresearch.com/passive-glider-market-20603

Company Name: DataHorizzon Research

Address: North Mason Street, Fort Collins,

Colorado, United States.

Mail: sales@datahorizzonresearch.com

DataHorizzon is a market research and advisory company that assists organizations across the globe in formulating growth strategies for changing business dynamics. Its offerings include consulting services across enterprises and business insights to make actionable decisions. DHR’s comprehensive research methodology for predicting long-term and sustainable trends in the market facilitates complex decisions for organizations.

This release was published on openPR.