Polycarbonate (PC) and Acrylonitrile-Butadiene-Styrene (ABS) alloys are widely used for automotive instrument panels, center consoles, and decorative trims due to their excellent impact strength, dimensional stability, and weather resistance.

However, during vehicle operation, vibrations and external pressure cause friction between plastic interfaces-or between plastics and materials such as leather or electroplated parts-resulting in the well-known “squeak” or “creak” noise.

This is primarily caused by the stick-slip phenomenon, where friction alternates between static and dynamic states, releasing energy in the form of sound and vibration.

Understanding Damping and Friction Behavior in Polymers

Damping refers to a material’s ability to convert mechanical vibration energy into heat energy, thus controlling vibration and noise.

The better the damping performance, the lower the audible squeak.

In polymer systems, damping is related to molecular chain relaxation – internal friction delays the response of deformation to stress, creating a hysteresis effect that dissipates energy.

Therefore, increasing internal molecular friction or optimizing viscoelastic response is key to improving acoustic comfort.

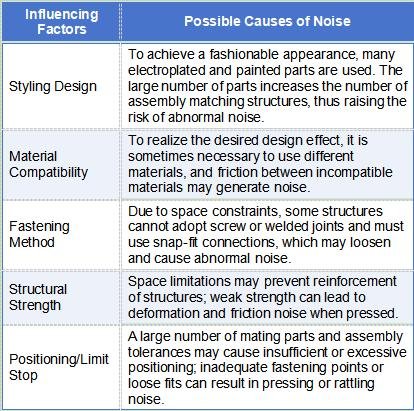

Table 1. Analysis of Abnormal Noise in Automotive Parts

Image: https://www.siliketech.com/uploads/Analysis-of-Abnormal-Noise-in-Automotive-Parts.png

Table 2. Challenges OEMs Face with Conventional Noise-Reduction Methods

However, these Conventional Noise-Reduction Methods not only increase labor costs but also prolong the production cycle of the products. Therefore, noise reduction modification has become the focus of attention for plastic modification manufacturers. Like some OEM automotive manufacturers collaborate with modified plastic material producers to develop various noise-reducing PC/ABS alloy materials. By improving the damping performance and reducing the friction coefficient of materials through formulation research and component validation, they apply the modified PC/ABS to instrument panels in multiple vehicle models. This effectively reduces cabin noise and helps create ultra-quiet, comfortable, and serene electric vehicles.

What modification technology enables this PC/ABS noise reduction breakthrough [https://www.siliketech.com/anti-squeaking-masterbatch/]

– Innovative Anti-Squeak Additives for ABS and PC/ABS.

An Automotive Interior Material Modification Breakthrough – SILIKE Anti-Squeak Masterbatch SILIPLAS 2073 [https://www.siliketech.com/anti-squeak-additive-masterbatch-siliplas2073-in-automotive-interior-product/]

To address this, SILIKE developed SILIPLAS 2073, a silicone-based anti-squeak additive designed for PC/ABS and ABS systems.

This innovative material enhances damping and reduces the coefficient of friction without compromising mechanical performance.

How it works:

During compounding or injection molding, SILIPLAS 2073 forms a micro-silicone lubricating layer on the polymer surface, reducing stick-slip friction cycles and long-term vibration noise.

Proven Noise Reduction – Verified by RPN Testing

At just 4 wt.% addition, SILIPLAS 2073 achieves an RPN (Risk Priority Number) of 1 under VDA 230-206 standards – well below the threshold (RPN < 3) that indicates a noise-free material.

Table 3. Comparison of Properties: Noise-Reduced PC/ABS vs. Standard PC/ABS

Note: RPN combines the frequency, severity, and detectability of squeak risk.

An RPN between 1-3 means minimal risk, 4-5 moderate risk, and 6-10 high risk.

Testing confirms that SILIPLAS 2073 effectively eliminates squeak even under varying pressure and sliding speeds.

Other test data

Image: https://www.siliketech.com/uploads/stick-slip-test-of-PCABS.png

It can be seen that the stick-slip pulse value of PC/ABS significantly decreases after adding 4% SILIPLAS 2073.

Image: https://www.siliketech.com/uploads/Anti-Squeak-Additives-for-PCABS.png

After adding 4% SILIPLAS2073, the impact strength has been improved.

Key Technical Benefits of SILIKE Anti-Squeak Masterbatch – SILIPLAS 2073

1. Effective Noise Reduction: Significantly lowers friction-induced squeaks in automotive interiors and e-motor components – RPN < 3 proven performance

2. Reduced Stick-Slip Behavior

3. Stable, Long-Lasting COF throughout the component’s service life

4. No Post-Treatment Required: Replaces complex secondary lubrication or coating steps right shorter production cycle

5. Maintains Mechanical Properties: Preserves strength, impact resistance, and modulus

6. Low Addition Rate (4 wt.%): cost efficiency and formulation simplicity

7. Free-Flowing, Easy-to-Process Granules for seamless integration into existing compounding or injection molding lines

8. Enhanced Design Flexibility: Fully compatible with ABS, PC/ABS, and other engineering plastics

SILIKE Silicone-Based Anti-Squeak Additive SILIPLAS 2073 [https://www.siliketech.com/anti-squeak-additive-masterbatch-siliplas2073-in-automotive-interior-product/] is not only designed for major automotive interior components – it can also be applied to household appliances made of PP, ABS, or PC/ABS. The addition of this additive helps prevent friction between parts and effectively reduces noise generation.

The Advantage of SILIKE anti-squeak additive for OEMs and Compounders

By integrating noise control directly into the polymer, OEMs and compounders can achieve:

Greater design freedom for complex geometries

Simplified production flow (no secondary coating)

Enhanced brand perception – silent, refined, premium EV experience

Why Engineers and OEMs Choose SILIPLAS 2073

In today’s automotive landscape-where quiet performance, lightweight design, and sustainable innovation define success-SILIKE SILIPLAS 2073 solution, a new way to prevent disturbing noise from plastic parts. It reduces reliance on heavy acoustic insulation materials. This silicone-based anti-squeak additive enables measurable noise reduction in PC/ABS alloys without post-treatment, ensuring cost efficiency, manufacturing simplicity, and compatibility with mass production.

Especially, as electric vehicles evolve, silence has become a mark of quality. With SILIPLAS 2073, acoustic comfort becomes an inherent material property, not an added step.

If you’re developing PC/ABS compounds or components that demand quieter performance, SILIKE’s silicone-based anti-squeak technology offers the proven solution. [https://www.siliketech.com/anti-squeak-additive-masterbatch-siliplas2073-in-automotive-interior-product/]

Experience quieter, smarter, and more efficient design – from the material modification level up.

Want to discover how SILIPLAS 2073 reduces noise and prevents squeaks with modified material technology?

Or, If you are looking for a high-performance noise reduction masterbatch or additive, you can try SILIKE noise reduction masterbatch, as this series of silicone additives will bring good noise reduction performance to your products. SILIKE’s anti-squeak masterbatch is suitable for application in all areas of daily life, such as household or automotive equipment, sanitary facilities, or engineering parts.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn. website:http://www.siliketech.com to learn more.

Media Contact

Company Name: Chengdu Silike Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-causes-squeaking-in-pcabs-automotive-and-ev-parts]

Country: China

Website: https://www.siliketech.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.