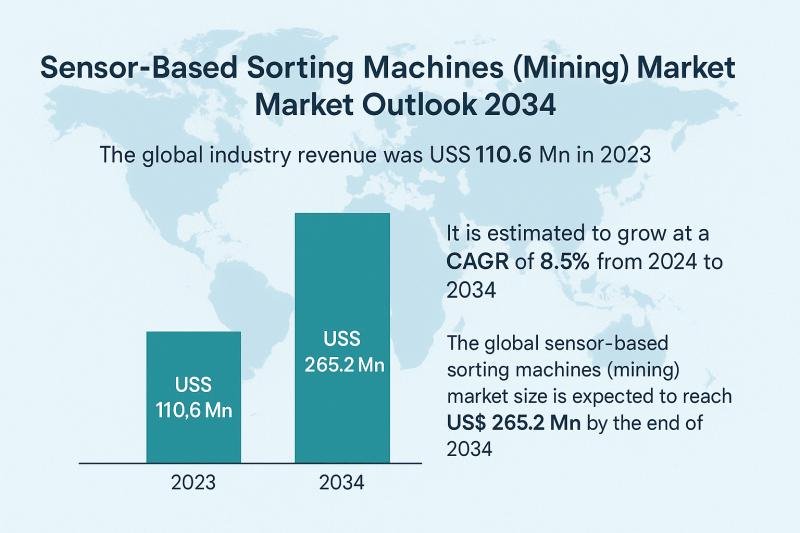

Sensor-Based Sorting Machines (Mining) Market Outlook 2034

The global sensor-based sorting machines (mining) market was valued at US$ 110.6 Million in 2023 and is projected to reach US$ 265.2 Million by 2034, expanding at a robust CAGR of 8.5% from 2024 to 2034. Growth is driven by rising demand for efficient ore processing, reduced energy consumption, and enhanced mineral recovery. The increasing adoption of automation and smart technologies in the mining industry is further propelling market expansion.

📥 Download your sample report copy now to unlock exclusive market data:

👉 https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85821

Market Overview

Sensor-based sorting machines in mining utilize advanced sensors-such as X-ray transmission (XRT), near-infrared (NIR), laser, electromagnetic, and color recognition-to detect and sort valuable minerals and ores from waste rock. These machines have become indispensable in modern mining operations, improving ore quality, reducing waste, and lowering operational costs.

The growing need for automation, precision sorting, and enhanced mineral recovery is driving adoption. Moreover, tightening regulations on waste reduction and environmental impact are encouraging miners to integrate smart sorting technologies in their processes.

Market Description

Sensor Technologies in Focus:

• X-ray Transmission (XRT): Ideal for high-throughput sorting of metal ores

• Near-Infrared (NIR): Effective in sorting industrial minerals such as quartz, limestone, and talc

• Laser and Optical Sorting: Used for surface mineral recognition

• Electromagnetic Sensors: Useful for detecting ferrous and non-ferrous metals

• Color & RGB Cameras: Suitable for coal and gemstone sorting

Common Applications:

• Pre-concentration of ores

• Waste rock removal

• Tailings recovery

• Upgrading low-grade ore

• Enhancing downstream processing efficiency

Analysis of Sensor-Based Sorting Machine Manufacturers

Manufacturers are investing heavily in AI-driven software, machine learning algorithms, and real-time sensor data integration. This enables not only faster sorting but also decision-making based on ore variability, enabling better yield and sustainability in mining.

📌 Sensor-based sorting is revolutionizing mining by improving throughput, enhancing precision, and reducing environmental impact.

Key Companies in the Market:

• TOMRA Systems ASA

• REDWAVE

• Steinert

• Sesotec GmbH

• Eriez Manufacturing Co.

• Mettler-Toledo International Inc.

• Cleanaway Waste Management Limited

• Varisort

• Haarslev Industries

• Buhler Sortex

• Other Key Players

Key Developments in the Sensor-based Sorting Machines (Mining) Market

• April 5, 2023 – REDWAVE launched the REDWAVE XRF fine sorting machine, revolutionizing the separation of fine non-ferrous metals in the metal recycling industry. Capable of sorting particles as small as 4 mm, this system leverages advanced X-ray fluorescence (XRF) technology to recover high-purity materials such as copper, brass, zinc, and precious metals. This development underscores REDWAVE’s push toward maximum material recovery and high output quality in complex sorting environments.

• February 27, 2023 – TOMRA Mining introduced a next-generation ejection module (TS100C) for its COM Tertiary XRT Fines sorter, aimed at enhancing the sorting of ultra-fine mineral particles (≥4 mm) in high-capacity operations. The sorter uses advanced image processing and X-ray transmission (XRT) technology to deliver up to 70% reduction in energy consumption at the industrial scale. This innovation reflects TOMRA’s deep commitment to sustainable mining practices and cost-efficient operations.

📌 Detailed strategy mapping is available in the sample report copy @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85821

Key Strategies by Manufacturers

🧠 AI & Machine Learning Integration

Manufacturers are embedding smart algorithms to auto-adjust sorting parameters based on real-time ore feed characteristics.

♻️ Sustainability and Resource Efficiency

Sensor-based sorting significantly reduces water and energy use, and minimizes chemical processing by eliminating waste rock early in the process.

📦 Modular and Mobile Units

Several companies now offer mobile sorting units for flexible use at multiple mine sites or temporary operations.

🛠️ Retrofitting Capabilities

Retrofittable sorting systems are gaining attention, allowing older plants to upgrade without significant structural change.

Challenges

• High Capital Investment

Sensor-based sorting machines are expensive to acquire and install, though they offer long-term ROI through operational savings.

• Material Heterogeneity

Complex ore compositions can reduce sorting accuracy, especially in highly variable feedstocks.

• Integration with Legacy Systems

Fitting high-tech systems into traditional mining setups can require technical expertise and infrastructural revamps.

• Training and Skilled Workforce

Operators and engineers need training to maintain and calibrate sensor technologies efficiently.

Opportunities

🌍 Declining Ore Grades Worldwide

As rich ore deposits deplete, miners are turning to advanced sorting to process low-grade ores economically.

📈 Growth in Critical & Rare Earth Minerals

The shift to electric vehicles, renewables, and semiconductors is driving demand for lithium, cobalt, and rare earth elements-areas where sensor-based sorting proves highly effective.

🪨 Tailings Reprocessing

Sensor-based machines help reclaim valuable minerals from tailings, turning waste into revenue.

🛤️ Remote and Autonomous Mines

As mining operations expand into remote terrains, sensor sorting reduces reliance on manual labor and downstream processing.

🧪 R&D in Sensor Technology

Breakthroughs in hyperspectral imaging and real-time analytics offer faster, more accurate material differentiation.

Market Segmentation

➤ By Sensor Type

• X-ray Transmission (XRT)

• Near-Infrared (NIR)

• Laser Sorting

• Color & Optical Sorting

• Electromagnetic Sorting

➤ By Application

• Metal Ores (Iron, Copper, Gold, etc.)

• Industrial Minerals

• Coal

• Gemstones

• Tailings and E-waste

➤ By Throughput Capacity

• 50 Tons per Hour

• 50-150 Tons per Hour

• 150 Tons per Hour

➤ By Deployment

• Fixed/Stationary Units

• Mobile/Containerized Units

➤ By Region

• Asia Pacific – Major market led by China, Australia, and India

• Europe – High-tech adoption and mining reforms supporting market growth

• North America – Strong R&D ecosystem and demand for critical minerals

• Latin America – Growth driven by copper and lithium mining

• Middle East & Africa – Increasing investment in gold and iron ore mines

🛒 Purchase the full report for strategic planning:

👉 https://www.transparencymarketresearch.com/checkout.php?rep_id=85821<ype=S

Why Purchase the Sensor-Based Sorting Machines (Mining) Report?

✅ Detailed Forecasts: Predictive insights on market behavior up to 2034

✅ Competitive Benchmarking: Analyze innovation, pricing, and footprint of key players

✅ Technology Deep Dive: Understand the evolution of sensors and AI in mining applications

✅ Policy & Regulation Insights: Stay informed about global mining reforms

✅ Investment Guidance: Ideal for OEMs, mining companies, investors, and sustainability leaders

Conclusion

The sensor-based sorting machines market in mining is gaining momentum as the industry modernizes for efficiency, sustainability, and profitability. As ore grades drop and regulations tighten, mining operators are turning to intelligent sorting to stay competitive and reduce environmental impact. Companies that adopt early, invest in AI-powered systems, and focus on sustainability will lead the next era of smart mining.

More Trending Research Reports-

• Slotting Machine Market – https://www.transparencymarketresearch.com/slotting-machine-market.html

• Tamping Rammer Machine Market – https://www.transparencymarketresearch.com/tamping-rammer-machine-market.html

About Us Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade.

Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact Us

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.