The Industry 4.0 market has experienced significant growth in recent years, driven by advancements in technology, increasing globalization, and a focus on improving manufacturing efficiency and productivity. This post will delve into the market, exploring its size, share, opportunities, challenges, demand, and trends.

Market Size and Share

The Industry 4.0 market is a substantial segment of the global manufacturing industry. While precise figures can vary depending on data sources and regional factors, the market is estimated to be worth billions of dollars. Key players in the market include established technology companies, industrial automation providers, and manufacturing firms.

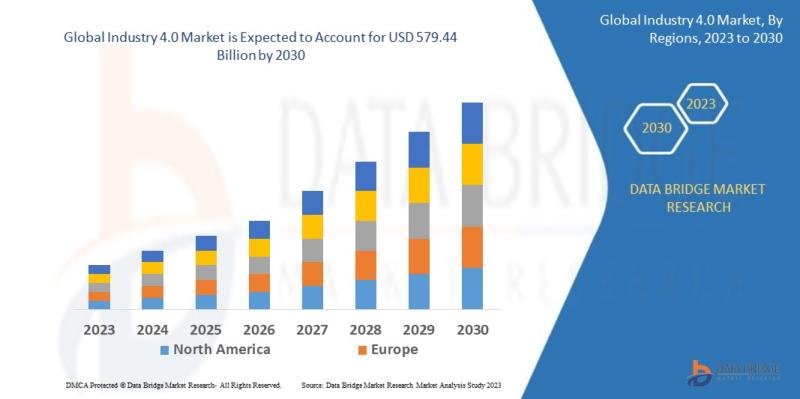

Data Bridge Market Research analyses that the industry 4.0 market, valued at USD 135.93 billion in 2022, will reach USD 579.44 billion by 2030, growing at a CAGR of 19.87% during the forecast period of 2023 to 2030. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

For more information, visit https://www.databridgemarketresearch.com/reports/global-industry-4-0-market

Market Opportunities

The Industry 4.0 market presents several significant opportunities:

Improved efficiency: Industry 4.0 technologies can optimize manufacturing processes, reduce waste, and increase productivity.

Enhanced decision-making: Data-driven insights from Industry 4.0 solutions can help manufacturers make informed decisions about production, quality control, and supply chain management.

Customization and personalization: Industry 4.0 enables manufacturers to offer customized and personalized products, meeting the diverse needs of consumers.

Predictive maintenance: Predictive maintenance using Industry 4.0 technologies can help prevent equipment failures and reduce downtime.

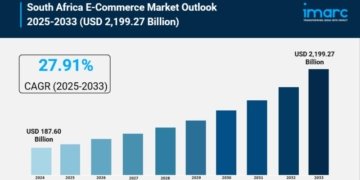

Emerging markets: The growth of emerging markets, particularly in Asia and Africa, is creating new demand for manufacturing technologies and solutions.

Market Challenges

Despite its growth potential, the Industry 4.0 market faces several challenges:

High upfront costs: The initial investment in Industry 4.0 technologies can be substantial, limiting adoption for smaller manufacturers.

Technological complexity: Implementing Industry 4.0 solutions can be complex, requiring specialized expertise and technical skills.

Data security and privacy: Protecting sensitive data generated by Industry 4.0 technologies is a critical concern.

Talent shortage: There is a shortage of skilled professionals with expertise in Industry 4.0 technologies, making it difficult for organizations to find qualified talent.

Regulatory compliance: Adhering to regulatory requirements related to data privacy, cybersecurity, and environmental standards can be challenging.

Market Demand

The demand for Industry 4.0 solutions is driven by several factors:

Improved efficiency and productivity: Manufacturers are seeking to improve their operational efficiency and reduce costs.

Product customization: Consumers are increasingly demanding customized products, which can be enabled by Industry 4.0 technologies.

Quality control: Ensuring product quality is essential for manufacturers, and Industry 4.0 can help improve quality control processes.

Supply chain management: Industry 4.0 can optimize supply chain operations, reducing lead times and improving inventory management.

Competitive advantage: Manufacturers that embrace Industry 4.0 can gain a competitive advantage by improving their operations and product offerings.

Market Trends

Several key trends are shaping the Industry 4.0 market:

Internet of Things (IoT): The widespread adoption of IoT devices is enabling the collection and analysis of real-time data from manufacturing processes.

Artificial intelligence (AI): AI-powered solutions are being used for tasks such as predictive maintenance, quality control, and automation.

Robotics: The use of robots in manufacturing is increasing, automating tasks and improving efficiency.

Cloud computing: Cloud-based platforms are providing scalable and flexible solutions for Industry 4.0 applications.

Digital twins: Digital twins, virtual representations of physical assets, are being used to simulate and optimize manufacturing processes.

Browse Trending Reports:

Global Iron Ore Mining Market – Industry Trends and Forecast to 2030 https://www.databridgemarketresearch.com/reports/global-iron-ore-mining-market

Global Sauces, Dressings and Condiments Market – Industry Trends and Forecast to 2030 https://www.databridgemarketresearch.com/reports/global-sauces-dressings-and-condiments-market

Global Bare Metal Cloud Market – Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-bare-metal-cloud-market

Global Pharmacogenetics Testing in Psychiatry/Depression Market – Industry Trends and Forecast to 2031 https://www.databridgemarketresearch.com/reports/global-pharmacogenetic-testing-in-psychiatry-depression-market

In conclusion, the Industry 4.0 market is a growing industry, driven by the need for improved efficiency, productivity, and competitiveness. As technology continues to advance and the benefits of Industry 4.0 become more apparent, the market is expected to experience further expansion and innovation.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: Corporatesales@databridgemarketresearch.com

Data Bridge Market Research:

Today’s trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

This release was published on openPR.