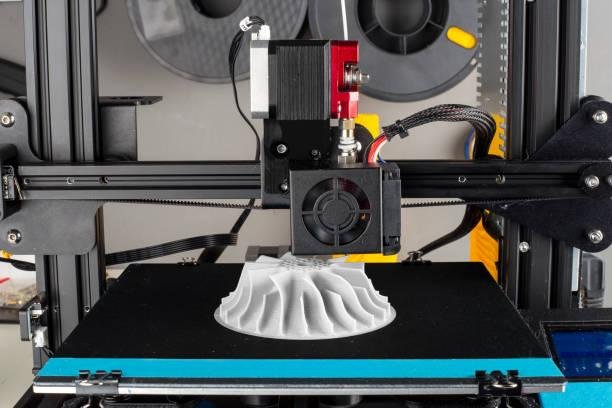

As the world continues to embrace digital transformation and rapid prototyping, the 3D Printing Services Market is poised for exponential growth. According to a recent analysis by Prophecy Market Insights, the global market was valued at USD 9.4 Billion in 2024 and is projected to grow at an impressive CAGR of 24.5%, reaching USD 83.4 Billion by 2035.

Get Sample Preview of The Report :- https://www.prophecymarketinsights.com/market_insight/Insight/request-sample/3900

This surge is fueled by the increasing adoption of additive manufacturing across sectors such as aerospace, medical, automotive, architecture, and electronics-marking a revolution in how products are designed, developed, and delivered.

What’s Fueling the Market?

The demand for on-demand production, rapid prototyping, and cost-efficient small-batch manufacturing is pushing industries toward 3D printing solutions. Key growth factors include:

Customization Capabilities: Especially relevant in medical prosthetics, dental implants, and fashion accessories.

Material Innovations: Emerging materials such as biocompatible polymers, reinforced plastics, and metal alloys are enhancing functionality and reliability.

Cost-Effectiveness: Reducing inventory costs and eliminating the need for expensive tooling and molds.

Design Freedom: Complex geometries that are impossible or cost-prohibitive with traditional methods are easily achievable with additive technologies.

Market Segmentation

By Technology:

Fused Deposition Modeling (FDM) – Popular for its affordability and wide material compatibility; ideal for consumer-grade and prototyping applications.

Stereo Lithography Apparatus (SLA) – High-resolution printing suitable for intricate designs in dental and jewelry industries.

Selective Laser Sintering (SLS) – Suitable for functional parts and small production runs due to high strength and accuracy.

Direct Metal Laser Sintering (DMLS) – Widely used in aerospace and defense for printing high-performance metal parts.

Others – Includes Binder Jetting, Electron Beam Melting (EBM), and Multi-Jet Fusion (MJF).

By Material:

Metal – Growing use in aerospace, defense, and automotive applications.

Plastic – Most common material in prototypes and consumer applications.

Ceramic – Utilized in electronics and medical applications.

Nylon – Known for strength and flexibility, ideal for mechanical parts.

Others – Includes composites, wax, bio-inks, and sandstone.

By End-User:

Electronics – Custom enclosures, circuit boards, and wearables.

Architecture & Designing – Rapid model prototyping and scale modeling.

Aerospace & Defense – Lightweight, durable parts for engines and structural components.

Medical & Healthcare – Dental devices, orthopedic implants, prosthetics, surgical tools.

Automobile – Tooling, jigs, fixtures, and low-volume functional parts.

Others – Includes fashion, education, and consumer goods.

By Region:

North America – Leading the charge in aerospace and healthcare adoption.

Europe – Home to several key players and supported by robust R&D.

Asia Pacific – Fastest-growing region, fueled by manufacturing growth in China, Japan, and India.

Latin America & Middle East – Emerging markets with increasing industrial digitization and innovation support.

Competitive Landscape

The global 3D Printing Services Market is moderately fragmented with several global and regional players striving to expand their capabilities, product offerings, and geographic reach.

Prominent Market Players:

Stratasys – A pioneer in FDM and PolyJet technologies, widely adopted in aerospace and healthcare.

HP Development Company, L.P. – Known for its Multi Jet Fusion (MJF) platform and end-to-end industrial solutions.

EOS GmbH – German-based leader in industrial 3D printing of metals and polymers.

Proto Labs – Offers rapid manufacturing services including CNC machining and injection molding alongside 3D printing.

THINK3D – Indian-based provider with rapid prototyping and mass customization capabilities.

3D Systems, Inc. – Offers SLA, SLS, and DMP solutions for industrial applications.

Nano Dimension – Specializes in electronics 3D printing, including PCBs and circuits.

voxeljet AG – Known for large-format industrial printers and service centers.

Shapeways – A digital manufacturing platform serving creators and small businesses.

Nikon SLM Solutions AG – Focused on metal additive manufacturing with high-end laser sintering technology.

Materialise – Provides software and on-demand manufacturing solutions, especially in healthcare.

Boson Machines – Known for high-resolution 3D printers and design support services.

IMIK Technologies – Offers industrial 3D printing services in emerging markets.

Xometry Europe GmbH – A digital manufacturing marketplace streamlining production services.

3D Spectra Technologies LLP – Indian firm known for customized solutions and prototyping excellence.

Get Sample PDF:- https://www.prophecymarketinsights.com/market_insight/Insight/request-pdf/3900

Recent Developments

March 2025: HP unveiled a new scalable 3D printing platform aimed at mass customization in footwear.

April 2025: EOS GmbH partnered with automotive manufacturers to develop lightweight engine components using DMLS.

June 2025: Materialise launched new software integration tools for hospitals to create customized implants directly from CT scans.

July 2025: Xometry expanded its digital network to include Latin American suppliers, broadening its global reach.

Business Relevance

The 3D printing services sector holds critical importance for:

Startups: Lower entry costs and rapid iteration cycles.

SMEs: Low-volume production without inventory risks.

Large Enterprises: Product development acceleration and localized production capabilities.

Government & Defense: On-demand part production and localized manufacturing for strategic operations.

Key Growth Strategies

Cloud Integration: Platforms offering online CAD customization, instant quotes, and real-time production tracking.

Vertical Integration: Companies acquiring material suppliers or design software providers to streamline processes.

Sustainability Initiatives: Focus on eco-friendly materials and waste reduction in additive manufacturing.

AI & Automation: Enhancing design optimization and process efficiency through AI-driven modeling.

Market Challenges

Despite exponential growth, the market faces challenges such as:

High Equipment Costs: Especially for metal 3D printing technologies.

Skill Gaps: Demand for engineers and designers trained in additive manufacturing is still unmet.

Intellectual Property Risks: Concerns over design piracy with digital files.

Regulatory Approvals: Particularly in the medical and aerospace sectors.

FAQs – 3D Printing Services Market

Q1. What is the projected value of the 3D printing services market by 2035?

A: The market is anticipated to reach USD 83.4 Billion by 2035.

Q2. What is the current growth rate of the market?

A: The market is expanding at a CAGR of 24.5% from 2024 to 2035.

Q3. Which technology holds the largest share?

A: FDM and SLS currently dominate due to cost-effectiveness and material flexibility.

Q4. What are the primary end-use industries?

A: Aerospace, medical, automotive, architecture, and electronics are key verticals.

Q5. Who are some key players in this market?

A: HP, Stratasys, 3D Systems, EOS GmbH, Materialise, and Xometry Europe GmbH are major players.

Author:

Shweta R., Business Development Specialist at Prophecy Market Insights

This article is based on extensive primary and secondary research, offering deep insights into the future of the 3D Printing Services Market.

India Office: Sai Ambience, Kunal Icon Rd, Pimple Saudagar, Pune

US Office: 964 E. Badillo Street #2042, Covina, CA 91724

US Toll-Free: +1 689 305 3270

Rest of World: +91 7775049802

Email: Sales@prophecymarketinsights.com

Website: http://www.prophecymarketinsights.com

About Prophecy Market Insights

Prophecy Market Insights is a market research and consulting firm delivering strategic insights, customized reports, and growth forecasts. With deep domain knowledge and a global outlook, our insights empower businesses to make confident, data-driven decisions.

This release was published on openPR.