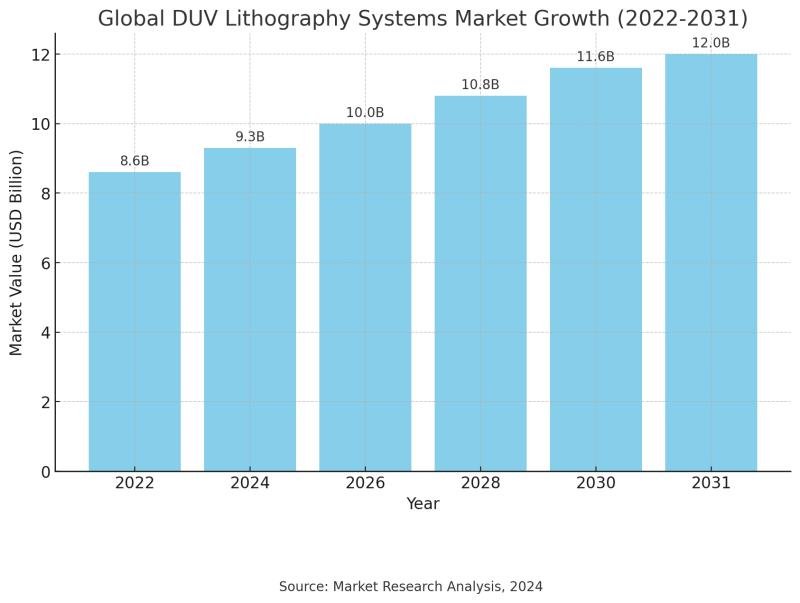

The global DUV lithography systems market, valued at USD 8.6 Bn in 2022, is poised for significant expansion with an anticipated CAGR of 4.1% during the forecast period 2023-2031. Driven by the growing semiconductor sector, rapid miniaturization of electronic components, and advances in wafer processing and fabrication capacities, the market is experiencing a transformative phase. Key industry players such as ASML, Canon Inc., and Nikon Precision Inc. are leading the way, paving the path for innovative solutions and technological breakthroughs.

Download to explore critical insights from our Report in this sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=83455

Market Overview

Deep Ultraviolet (DUV) lithography is a cornerstone technology in the semiconductor industry, critical for producing smaller, faster, and more energy-efficient electronic devices. This advanced photolithography technology employs light wavelengths of 193 nm or 157 nm to transfer intricate circuit patterns onto silicon wafers. By enabling the patterning of sub-10 nm features, DUV lithography supports the fabrication of high-density transistors essential for integrated circuits and advanced packaging solutions, including Fan-out Wafer Level Packaging (FOWLP) and System-in-Package (SiP) devices.

The growing demand for miniaturized electronics, combined with expanding wafer processing capacities, underscores the vital role that DUV lithography plays in the semiconductor value chain. With increasing investments in semiconductor fabrication and robust R&D initiatives by industry leaders, the market is set to witness accelerated growth, particularly in regions such as Asia Pacific, where technological adoption is rapidly evolving.

Market Drivers & Trends

Advancements in Miniaturization:

The relentless drive towards miniaturization in the electronics sector is a key market driver. As semiconductor manufacturers strive to pack more functionality into smaller chip footprints, DUV lithography systems become indispensable. The ability to pattern increasingly fine structures allows for the development of high-performance, low-power chips that meet the stringent demands of next-generation applications such as 5G, Artificial Intelligence (AI), and Internet of Things (IoT) systems.

Expansion in Wafer Processing & Fabrication:

Enhanced wafer processing capabilities have been a major contributor to the market’s growth. As companies invest in expanding their fabrication capacities, DUV lithography systems enable faster throughput and improved efficiency. This has led to a reduction in the cost per chip, making advanced semiconductor devices more accessible across various industries. The integration of sophisticated lithography techniques has also facilitated the manufacturing of devices with superior performance characteristics.

Adoption of KrF Lithography:

Among the various types of DUV lithography systems, the KrF (Krypton Fluoride) segment has emerged as a prominent player due to its high resolution and capability to produce intricate circuit designs. KrF lithography, which utilizes ultraviolet light from a KrF excimer laser, is favored for its reliability in fabricating advanced integrated circuits and high-end computing devices. This trend has been further boosted by strategic product launches and enhancements by market leaders.

Technological Innovation and Product Upgrades:

Continuous innovation and regular product upgrades are pivotal in maintaining market momentum. For instance, Canon Inc. recently introduced its “Grade 10” productivity upgrade option for its FPA-6300ES6a KrF semiconductor lithography equipment, enhancing throughput to 300 wafers per hour. Such advancements not only improve production efficiency but also fortify the competitive edge of key players in the market.

Key Players and Industry Leaders

The global DUV lithography systems market is characterized by a consolidated competitive landscape with a few dominant players steering the industry. Major companies include:

ASML: Known for its cutting-edge lithography solutions, ASML continues to drive innovation in the semiconductor manufacturing process.

Canon Inc.: With continuous investments in technology upgrades and new product launches, Canon has strengthened its position, particularly with its recent “Grade 10” productivity upgrade.

Nikon Precision Inc.: Focused on developing high-performance lithography systems, Nikon is at the forefront of technological advancements, including next-generation immersion scanners.

These industry giants are heavily investing in research and development to push the boundaries of lithography technologies. Their strategic initiatives, product innovations, and expansive product portfolios have significantly influenced market trends and spurred competition within the sector.

Recent Developments

The market has seen a series of notable developments in recent years that are reshaping its trajectory:

Canon Inc. Launches Lithography Plus1 Solution: In September 2022, Canon Inc. introduced its Lithography Plus1 solution platform, which provides enhanced analytical capabilities for system status, maintenance scheduling, and downtime analysis. This development is expected to optimize operational efficiency and extend the lifespan of lithography systems.

Nikon’s Next-Generation Scanner: In October 2021, Nikon Precision Inc. announced the development of the NSR-S636E ArF immersion scanner. This next-generation scanner is designed to deliver superior overlay accuracy and ultra-high throughput, meeting the increasing demands for higher performance in semiconductor fabrication.

Expansion in Wafer Production: The foundry segment, which dominated the market with a 66.0% share in 2022, continues to expand as semiconductor manufacturers increase their wafer production capabilities. Notably, companies such as TSMC have achieved significant capacity expansions, with annual outputs surpassing 12 million 12-inch equivalent wafers.

These strategic developments underscore the dynamic nature of the market and highlight the continuous push towards innovation and operational excellence.

Review our report to gain deeper insights and understanding – https://www.transparencymarketresearch.com/duv-lithography-systems-market.html

Market Restraints & Challenges

Despite promising growth prospects, the DUV lithography systems market faces certain challenges:

High Capital Expenditure:

The initial cost of DUV lithography systems is substantial, which may deter smaller semiconductor manufacturers from adopting the technology. High capital expenditure, combined with the cost of ongoing maintenance and upgrades, represents a significant barrier to entry for new market participants.

Technological Complexity:

The intricate nature of DUV lithography systems, requiring specialized optics, precision illumination, and advanced photoresists, adds to the complexity of the manufacturing process. This technological complexity necessitates continuous R&D investments and highly skilled personnel, which can be a constraint for some companies.

Competition from Alternative Technologies:

While DUV lithography remains a critical tool for semiconductor manufacturing, emerging technologies such as extreme ultraviolet (EUV) lithography are gaining traction. Although EUV lithography is currently more expensive and less mature, its potential to further miniaturize semiconductor devices could challenge the dominance of DUV systems in certain segments.

Market Segmentation

The DUV lithography systems market is segmented based on type, end-use, and region:

Type:

ArF Immersion

ArF Dry

KrF

The KrF segment is projected to lead the market due to its high resolution and extensive application in the production of advanced integrated circuits.

End-use:

Integrated Device Manufacturers (IDM)

Foundry

The foundry segment held a significant market share in 2022, driven by the rapid increase in wafer production capacities.

Regional Segmentation:

Americas

Asia Pacific

EMEA

These segments provide valuable insights into the diverse applications and regional trends, enabling stakeholders to develop targeted strategies for market penetration and expansion.

Future Outlook

Looking ahead to 2031, the global DUV lithography systems market is set to achieve a market value of approximately US$ 12.3 Bn. The steady growth trajectory is underpinned by several factors:

Continued Technological Innovation:

Ongoing R&D efforts aimed at enhancing system capabilities and production efficiency will play a crucial role in driving market expansion.

Expansion of Semiconductor Fabrication Capacities:

The increasing demand for faster, more efficient electronic devices will necessitate further investments in wafer fabrication facilities and advanced lithography systems.

Growing Adoption of Miniaturized Electronics:

As electronic devices become more compact and multifunctional, the demand for high-resolution lithography systems will continue to rise.

Opportunities in Emerging Applications:

The integration of semiconductor chips in applications such as 5G, AI, and IoT is anticipated to open new avenues for growth, reinforcing the market’s long-term prospects.

Buy this Premium Research Report and access vital insights and analysis – https://www.transparencymarketresearch.com/checkout.php?rep_id=83455<ype=S

Why Buy This Report?

Investing in the comprehensive Global DUV Lithography Systems Market report provides invaluable insights into a rapidly evolving industry. The report covers:

In-Depth Market Analysis:

Detailed breakdowns of market trends, drivers, restraints, and growth opportunities.

Strategic Guidance:

Actionable recommendations and analysis of competitive dynamics to help stakeholders navigate the complex market landscape.

Data-Driven Forecasts:

Robust forecasts supported by historical data and trend analyses to guide strategic planning and investment decisions.

Regional Insights:

A thorough examination of regional trends and growth potentials, offering a global perspective on market dynamics.

Comprehensive Segmentation:

Detailed segmentation by type, end-use, and geography, enabling targeted decision-making for business expansion.

This report is an essential tool for industry professionals, investors, and business leaders seeking to gain a competitive edge in the semiconductor sector and understand the evolving dynamics of DUV lithography systems.

Explore Latest Research Reports by Transparency Market Research:

3D Imaging Market: https://www.transparencymarketresearch.com/3d-imaging-market.html

Biophotonics Market: https://www.transparencymarketresearch.com/biophotonics-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.