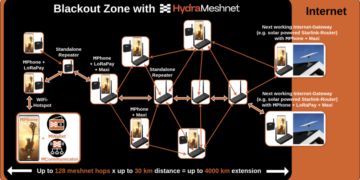

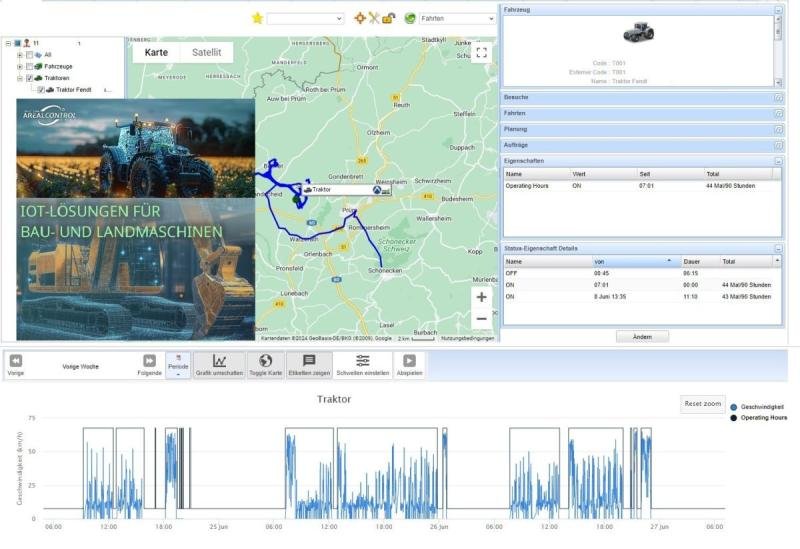

IoT can differentiate: Engine hours, production hours and stay hours per job site. (© Screenshot / Photo: AREALCONTROL GmbH)

Stuttgart, February 12, 2025 – Arealcontrol presents an innovative telematics solution that sustainably increases the efficiency and profitability of construction and agricultural machinery. The system precisely records the engine and production/working hours of construction machinery in real time and combines this data with GPS positioning to ensure precise billing, optimized maintenance planning and maximum data security.

Precise recording for transparent billing and optimized processes

Conventional methods of recording operating hours are often inaccurate and time-consuming. The new telematics solution from Arealcontrol sets new standards here with Bluetooth tags 4.0, which provide several sensor values: By combining engine hours and working hours recording of the machine in motion and in conjunction with GPS tracking of the machine location in the construction site area, the system enables pinpoint billing of machine performance. This creates transparency for customers and internal cost centres and minimizes potential conflicts. All data can flow into other systems via REST API.

“With our solution, construction companies have full control over the use of their machines at all times,” explains Ulric Rechtsteiner, Managing Director. “The requests came from construction companies for precise recording and differentiation of hour types. With the new solution, we not only enable correct billing, but also the identification of idle and unproductive times. This allows processes to be optimized and machine utilization to be increased. Especially on large construction sites for logistics management.”

Live status “Idle or production mode” for construction site logistics

Real-time transmission of the machine status is of crucial importance for optimum utilization of excavators, crawlers, wheel loaders and dumpers, especially on large-scale construction sites covering several kilometers. The current operating mode (idling or production) is transmitted live and enables efficient scheduling. Idle machines can thus be supplied with material immediately. Unproductive fuel consumption and unnecessary engine hours are avoided, resulting in considerable cost savings.

Predictive maintenance and minimized downtime

Recording engine hours enables predictive maintenance planning. By knowing the exact operating hours, maintenance intervals can be optimally planned and unplanned downtime minimized. This saves costs and increases machine availability.

An individually adjustable fleet and machine management system enables scheduling and document management, including history and reporting. “Workshop 4.0 concepts” can be implemented using machine learning.

Maximum data security and availability thanks to private cloud in tier 3 data centers

The collected data is provided via a user-friendly portal that is hosted as a private cloud in two mirrored Tier 3 data centers. This highly available infrastructure ensures continuous access to the data and protects against data loss. The private cloud also offers the highest security standards and protects sensitive data from unauthorized access.

“The security and availability of our customers’ data is our top priority,” emphasizes Ulric Rechtsteiner. “By hosting in mirrored Tier 3 data centers and a private cloud, we guarantee reliable access to the data and protect it to the highest standards.”

Summary

* Accurate billing: Transparent and correct billing of machine services.

* Optimized maintenance planning: Predictive maintenance and minimized downtimes.

* Increased efficiency: Identification of idle times and increased machine utilization.

* Theft protection and location determination: real-time location of machines with area monitoring (geofencing), time monitoring.

* Maximum data security and availability: hosting in mirrored Tier 3 data centers as a private cloud.

* Digitalization through automated data collection and billing.

* Improved cost control: precise recording of operating costs.

Technically, the solution is independent of the machine manufacturer and can be installed in all construction or agricultural machinery in just a few minutes. The payback period is practically just a few weeks.

KfdM – Kommunikation für den Mittelstand

Schulstr. 29

84183 Niederviehbach

Germany

Herr Marcus Walter

0170-7736705

AREALCONTROL GmbH, founded in 2003, is a provider of telematics & IoT solutions with optional GPS positioning and tracking as well as software for transport/logistics, trade, craft and construction companies and medium-sized industry. Today, the company offers multiple award-winning solutions for fleet and vehicle fleet requirements in many applications and industries. Most recently, AREALCONTROL won 1st place in the German Telematics Award 2024 and previously in 2022, category “Field Service”, 1st place for service cars in 2018 and several 2nd and 3rd places in 2018 – 2020 in truck categories.

This release was published on openPR.