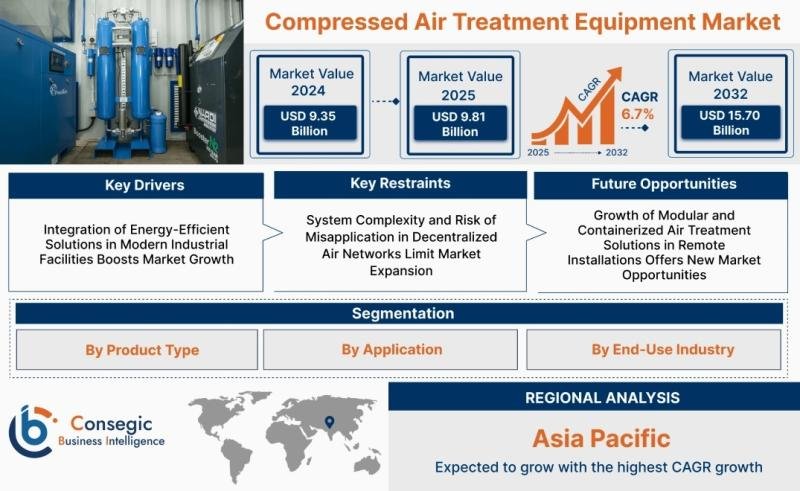

Compressed Air Treatment Equipment Market Introduction

The Compressed Air Treatment Equipment Market is a vital and expanding sector, offering essential solutions for a diverse range of industrial applications. Often considered the fourth utility, compressed air is extensively used across manufacturing, automotive, food & beverage, and pharmaceutical industries to power tools, pneumatic equipment, and critical machinery. However, untreated compressed air contains contaminants such as moisture, oil, and particulates. These impurities can lead to equipment damage, reduced efficiency, increased maintenance costs, product contamination, and significant downtime. This market provides solutions to purify compressed air to specific quality standards, ensuring optimal performance, extended equipment life, and process safety.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/2813

The market’s robust growth is primarily driven by increasing industrialization and automation, especially in emerging economies, which elevates the demand for clean and dry compressed air. Stricter regulatory requirements for air quality and environmental protection, particularly in sensitive sectors like food & beverage and pharmaceuticals, are also propelling market expansion. Furthermore, a rising awareness among industries about energy efficiency and sustainability encourages the adoption of advanced air treatment technologies. These technologies not only enhance air quality but also contribute to substantial energy savings by minimizing pressure drops and improving overall system efficiency.

• Market Size

Compressed Air Treatment Equipment Market size is estimated to reach over USD 15.70 Billion by 2032 from a value of USD 9.35 Billion in 2024 and is projected to grow by USD 9.81 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

• Definition of Market

1) The Compressed Air Treatment Equipment Market encompasses all products, services, and systems designed to eliminate contaminants from compressed air, ensuring its purity and suitability for various industrial uses.

2) Key components of this market include various equipment types, each serving a distinct purification purpose. Filters are essential for removing solid particles, oil aerosols, and odors.

3) Aftercoolers reduce compressed air temperature immediately after compression, condensing water vapor into liquid for removal. Oil/water separators manage collected condensate, separating oil from water for environmentally responsible disposal.

Request a Custom Quote: https://www.consegicbusinessintelligence.com/request-discount/2813

• Market Scope and Overview

1) The scope of the Compressed Air Treatment Equipment Market is extensive, covering a wide array of technologies, applications, and industries globally. Technologies include mechanical filtration, refrigeration-based drying, desiccant adsorption drying, membrane separation, and advanced condensate management systems. These technologies continuously evolve, with innovations focused on enhanced efficiency, reduced energy consumption, and improved contaminant removal.

2) Applications for treated compressed air are diverse and critical across numerous sectors. From powering pneumatic tools and operating automated machinery in manufacturing to ensuring sterile environments in pharmaceutical production and clean air for breathing apparatus in healthcare, the demand for high-quality compressed air is pervasive.

• Market Segmentation

The Compressed Air Treatment Equipment Market is segmented based on product type, application, and end-use industry. This segmentation provides a detailed view of the market, highlighting diverse needs and growth drivers within each category.

• By Product Type

• Filters: Essential for removing solid particles, oil aerosols, and other impurities from compressed air.

1) Particulate Filter/Pre-filter: First line of defense, removing larger solid particles and bulk liquids. They protect downstream equipment and enhance efficiency of other components.

2) Coalescing Filter/Oil Removal: Highly efficient at removing oil aerosols and fine particulate matter. They coalesce tiny oil and water droplets into larger ones for drainage, providing cleaner air.

3) Activated Carbon Filter: Specialized for removing oil vapors and odors. Activated carbon adsorbs hydrocarbons, delivering extremely clean, oil-free air crucial for sensitive applications.

• Dryers: Critical for removing moisture from compressed air, preventing corrosion, freezing, and microbial growth.

Get Started – Purchase Now: https://www.consegicbusinessintelligence.com/secure-checkout/2813

1) Refrigerated Dryers: Most common type, cooling air to near freezing, condensing water vapor for drainage. Energy-efficient for specific pressure dew point ranges.

2) Desiccant Dryers: Use adsorbent materials to remove moisture by adsorption, achieving very low pressure dew points. Ideal for critical applications sensitive to moisture.

• Oil/Water Separators: Separate oil from collected condensate, allowing for safe and environmentally compliant disposal of oil and discharge of treated water.

1) Drains: Manual or automatic devices that remove collected liquid condensate from various points, crucial for preventing moisture re-entrainment.

2) Others: Supplementary equipment like pressure regulators, air receivers (storage tanks), and particulate monitors that contribute to overall system efficiency and quality control.

• Top Key Players and Market Share Insights:

1) Atlas Copco AB (Sweden)

2) BOGE Kompressoren Otto Boge GmbH & Co. KG (Germany)

3) BEKO Technologies GmbH (Germany)

4) Elgi Equipments Limited (India)

5) Chicago Pneumatic (USA)

6) Kaeser Kompressoren SE (Germany)

7) Ingersoll Rand Inc. (USA)

8) Donaldson Company, Inc. (USA)

9) Parker-Hannifin Corporation (USA)

10) MANN+HUMMEL GmbH (Germany)

Access Full Report: https://www.consegicbusinessintelligence.com/compressed-air-treatment-equipment-market

• By Application

1) Plant Air: General-purpose compressed air used throughout manufacturing facilities for pneumatic tools, general machinery, and cleaning, requiring moderate treatment for equipment protection and reliability.

2) Instrument Air: Highly purified compressed air for sensitive control systems, instrumentation, and pneumatic actuators. Requires very low dew points and stringent filtration to protect delicate instruments and ensure precise control.

3) Process Air: Compressed air in direct contact with products or processes, especially in food & beverage, pharmaceuticals, and chemicals.

• By End-Use Industry

1) Manufacturing: Major consumer of compressed air for operating machinery, pneumatic conveying, assembly lines, and general utilities, requiring diverse treatment to ensure efficiency and protect assets.

2) Food & Beverage: Stringent air purity requirements due to direct product contact. Air is used for bottling, packaging, conveying, etc. Demands oil-free air and very low dew points to prevent contamination.

3) Pharmaceuticals: Similar to food & beverage, requires extremely high air purity for sterile environments, tablet pressing, and product handling.

• Market Drivers

1) Increasing Industrialization and Automation: Rapid industrial growth, especially in emerging economies, significantly boosts the demand for compressed air in manufacturing, automotive, and other sectors.

2) Stringent Air Quality Regulations: Global governments and regulatory bodies are imposing stricter air quality standards in industrial processes, particularly in sensitive sectors like food & beverage, pharmaceuticals, and healthcare.

3) Growing Emphasis on Energy Efficiency: Industries are increasingly focused on reducing energy consumption and operational costs. Compressed air systems are major energy consumers, and untreated air can lead to pressure drops, leaks, and inefficiencies, resulting in higher energy bills.

• Market Key Trends

1) Integration of IoT and Industry 4.0: A growing trend involves incorporating IoT (Internet of Things) capabilities into compressed air treatment equipment. This enables real-time monitoring of air quality, pressure dew point, filter life, and energy consumption. Predictive maintenance, remote diagnostics, and optimized operational insights are becoming standard, improving system uptime and efficiency.

2) Focus on Energy-Efficient Solutions: With rising energy costs and environmental concerns, manufacturers are heavily investing in developing energy-saving air treatment technologies. This includes demand-side control systems for dryers, heatless desiccant dryers with improved regeneration cycles, and filters with lower pressure drop, all aimed at minimizing the overall energy footprint of compressed air systems.

3) Demand for Higher Purity Air: Industries like electronics, semiconductors, and specialized manufacturing increasingly require ultra-high purity compressed air. This drives demand for advanced multi-stage filtration systems, oil-free compressors, and desiccant dryers capable of achieving very low dew points.

4) Rise of Compressed Air as a Service (CAaaS): Some companies are transitioning to service-based models where equipment manufacturers or third-party providers manage the entire compressed air system, including treatment.

• Market Opportunities

1) The Compressed Air Treatment Equipment Market offers significant growth prospects and opportunities, primarily driven by expanding industrialization, stringent regulatory frameworks, and technological advancements. The increasing global focus on energy efficiency and sustainability presents a substantial opportunity for manufacturers to innovate and provide more eco-friendly solutions. The rising demand for high-purity compressed air in sensitive industries like pharmaceuticals, food & beverage, and electronics opens doors for specialized, high-performance filters and dryers.

2) Moreover, the integration of smart technologies, such as IoT-enabled monitoring and predictive maintenance, provides a significant avenue for growth. This allows for optimized system performance, reduced downtime, and lower operational costs for end-users, creating a strong value proposition for advanced equipment.

3) Innovations in materials science are leading to more durable and efficient filter media and desiccant materials, extending equipment life and reducing replacement frequency. Furthermore, the development of integrated, modular treatment packages that simplify installation and maintenance presents an attractive opportunity for both manufacturers and end-users, streamlining the overall compressed air system.

• Market Restraints

1) Despite significant growth opportunities, the Compressed Air Treatment Equipment Market faces several restraints. A primary challenge is the high initial cost associated with advanced treatment equipment, especially for high-purity applications or large industrial systems. This capital expenditure can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. Geographic limitations, particularly in developing regions, can also pose a restraint due to inadequate infrastructure, lack of skilled personnel for installation and maintenance, and limited access to spare parts.

2) Furthermore, a general lack of awareness among some end-users about the critical importance of proper compressed air treatment and the long-term benefits of investing in quality equipment can hinder market penetration. Technical factors such as the complexity of integrating diverse treatment components into existing systems, the need for regular maintenance, and the potential for pressure drops across filters and dryers (leading to energy losses if not properly managed) can also act as barriers.

• Market Challenges

1) The Compressed Air Treatment Equipment Market, while buoyant, faces several significant challenges that can impact its growth and widespread adoption. One major challenge is the lack of comprehensive awareness and understanding among some industrial end-users regarding the profound impact of untreated compressed air on their operations. Many businesses still view compressed air as a “free utility” or an afterthought, failing to recognize the hidden costs associated with contaminated air – such as premature equipment wear, increased maintenance, product spoilage, and significant energy losses. This lack of awareness often leads to underinvestment in proper air treatment solutions or the use of inadequate, lower-cost equipment that fails to meet required purity standards.

2) Finally, the rapid pace of technological change demands continuous investment in research and development for manufacturers to remain competitive. While this drives innovation, it also means that older equipment can quickly become outdated, creating a challenge for companies seeking to upgrade their systems economically.

•Market Regional Analysis

The Compressed Air Treatment Equipment Market exhibits diverse dynamics across different regions, influenced by varying industrial landscapes, regulatory environments, and economic development levels. Each region presents unique opportunities and challenges:

• North America (the United States, Canada, and Mexico)

• Europe (Germany, France, UK, Russia, and Italy)

• Asia-Pacific (China, Japan, Korea, India, and Southeast Asia)

• South America (Brazil, Argentina, Colombia, etc.)

• The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

• Frequently Asked Questions

1) What is the projected growth rate (CAGR) for the Compressed Air Treatment Equipment Market from 2025 to 2032?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% from 2025 to 2032.

2) What is the estimated market size of the Compressed Air Treatment Equipment Market by 2032?

The market is expected to reach USD 15.70 Billion by 2032.

3) What are the key drivers for growth in this market?

Key drivers include increasing industrialization and automation, stringent air quality regulations, a growing emphasis on energy efficiency and sustainability, and the need to protect expensive downstream equipment from contamination.

4) Which industries are the major end-users of compressed air treatment equipment?

Major end-user industries include manufacturing (automotive, electronics, general), food & beverage, pharmaceuticals, healthcare, chemicals & petrochemicals, and energy & power.

Consegic Business intelligence Pvt Ltd.

B 202 , 2nd Floor, Ujwal Serene, Baner Road, Baner, Pune, Maharashtra – 411045.

Contact No: (US) (505) 715-4344

Email: sales@consegicbusinessintelligence.com

About Us:

At Consegic Business Intelligence Pvt. Ltd., we empower businesses with actionable insights and innovative market intelligence solutions. Our tailored research and data-driven strategies help organizations navigate complex industry landscapes and make confident decisions.

Specializing in market research, consulting, and competitive analysis, we deliver precise and holistic insights across global and regional markets. Our client-focused approach ensures customized solutions that drive growth and foster informed decision-making.

This release was published on openPR.