Allied Market Research published an exclusive report, titled, “Industrial Sensors Market By Sensor Type (Image Sensor, Pressure Sensor, Temperature Sensor, Level Sensor, Position Sensor, Humidity Sensor, Force Sensor, and Others), and Industry Vertical (Manufacturing, Pharmaceutical, Chemical, Oil & Gas, Energy & Power, and Mining): Global Opportunity Analysis and Industry Forecast, 2020-2027”.

Sensors are essential in industrial automation, delivering real-time data on processes and equipment. This data enables informed decision-making and precise control over critical parameters such as temperature, pressure, flow, level, and position. Various types of sensors, each with distinct capabilities and characteristics, play a key role in optimizing industrial operations.

Download Research Report Sample & TOC : https://www.alliedmarketresearch.com/request-sample/8508

Industrial sensors are highly beneficial in enhancing efficiency and productivity in the manufacturing process by delivering accurate and timely data. They enable operators to optimize production, minimize waste, and achieve significant cost savings, boosting profitability. In addition, sensors contribute to improved product quality and safety by detecting and preventing defects or anomalies during the production process.

A brief on industrial sensors

Industrial sensors are advanced devices that measure physical parameters such as temperature, pressure, humidity, and flow rate. Their ability to provide real-time data enables operators to detect and respond to changes swiftly, minimizing errors and ensuring high-quality output. These sensors perform reliably in harsh environments, withstanding extreme temperatures, vibrations, and high humidity. These sensing devices are highly versatile due to their greater versatility across various applications, allowing seamless operation even in challenging and inaccessible settings.

Exploring popular industrial sensors

A diverse range of manufacturing sensors and process controls are designed to monitor and collect data on various processes, parameters, and equipment performance metrics. In industrial automation, sensors serve specific functions, and their selection aligns with the equipment in use and the objectives of the predictive maintenance strategy.

Request For Customization @ https://www.alliedmarketresearch.com/request-for-customization/8508?reqfor=covid

One of the commonly used industrial sensors is the temperature sensor. It is mainly utilized to measure a material or an environment. Temperature sensors come in various types, categorized as contact or non-contact sensors. Contact sensors, such as thermocouples and resistance temperature detectors (RTDs), need direct contact with the material to measure its temperature accurately. However, non-contact temperature sensors, such as infrared sensors, detect an object’s temperature without requiring direct physical contact. Digital temperature sensors are widely used in industries such as food processing, pharmaceuticals, and metallurgy.

On the other hand, humidity sensors play an important role in industrial applications by ensuring precise moisture control. Widely used in agriculture, pharmaceuticals, and HVAC systems, they help maintain optimal environmental conditions for processes and storage. These sensors enhance product quality, prevent moisture-related damage, and support the efficient operation of industrial equipment by accurately measuring humidity levels, contributing to overall reliability and performance.

Moreover, pressure sensors measure the pressure of liquids, gases, or vapors by detecting pressure changes and converting them into electrical signals. They are extensively used in industries such as chemical, oil & gas, and automotive to monitor and regulate fluid pressure in pipelines, tanks, and engines, ensuring safe and efficient operations.

IIoT and cloud connectivity transforming industrial sensor technology

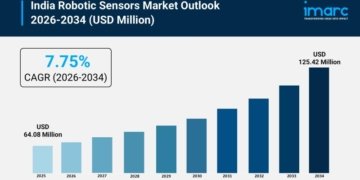

The industrial sensors industry has witnessed significant growth due to rapid technological advancements in these sensing devices. According to Allied Market Research, the sector is projected to rise at a CAGR of 9.77% from 2020 to 2027. Modern industrial sensors are becoming smaller and more sensitive owing to the latest advancements in microelectromechanical systems technology. These compact sensors are able to monitor parameters such as temperature, pressure, and vibration with high precision, even in harsh environments such as extreme heat or corrosive settings.

Moreover, industrial sensors are increasingly designed to integrate seamlessly with IIoT platforms. These smart sensors collect real-time data on parameters, including machine health, production efficiency, and environmental conditions. The data is then transmitted to cloud-based systems for analysis, enabling predictive maintenance and reducing downtime. For instance, Endress+Hauser’s cloud-connected radar system combines wireless IIoT sensor technology with user-friendly digital services, offering transparency in liquid storage and transport.

ABB and Sensorfact joined hands to strengthen energy efficient solutions

In January 2025, ABB, a Swedish multinational electrical engineering corporation, acquired Sensorfact BV, a fast-growing energy management company headquartered in Utrecht, Netherlands. The acquisition is expected to expand the digital energy management offerings of ABB. Massimiliano Cifalitti, the president of ABB’s Smart Power division, stated that ABB and Sensorfact share a commitment to enhancing energy efficiency, lowering maintenance costs and optimizing production. He emphasized that ABB is expanding its energy management portfolio by leveraging big data and AI to improve electrical distribution and efficiency. This acquisition aligns with ABB’s digital strategy, offering customers innovative solutions to digitalize manufacturing operations, making them more sustainable and efficient.

Inquiry Before Buying : https://www.alliedmarketresearch.com/purchase-enquiry/8508

The essence

Industry sensors play a vital role in industrial automation by providing real-time data that is used to make operational decisions and control various aspects of the industrial process. Their enhanced capabilities such as safety and security, predicting maintenance, increasing energy efficiency, and controlling the quality of products help monitor and controlvarious aspects of the industrial process. The the growing adoption of and development of the IIoT are expected to offer huge opportunities for the sector in the coming years.

Read More Reports :

https://www.alliedmarketresearch.com/optical-detector-market-A16497

https://www.alliedmarketresearch.com/fluid-sensors-market-A16493

https://www.alliedmarketresearch.com/eo-ir-gimbal-market-A06283

Contact:

David Correa

1209 Orange Street,

Corporation Trust Center,

Wilmington, New Castle,

Delaware 19801 USA.

Int’l: +1-503-894-6022

Toll Free: +1-800-792-5285

Fax: +1-800-792-5285

help@alliedmarketresearch.com

Web:https://www.alliedmarketresearch.com

About us :

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies, and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

This release was published on openPR.