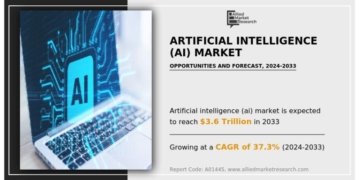

[292 Pages Report] The AI-Driven Supply Chain Resilience Market is transforming global logistics from a reactive, fragile system into a proactive, “self-healing” ecosystem. Post-pandemic disruptions, geopolitical tensions, and climate instability have killed the era of purely “Just-in-Time” efficiency; the new mandate is “Just-in-Case” resilience. This market involves the deployment of Artificial Intelligence (AI) and Machine Learning (ML) to map multi-tier supply networks, predict disruptions (like port strikes or raw material shortages) weeks in advance, and automatically execute mitigation strategies. It utilizes Digital Twins to simulate “Black Swan” events, allowing companies to stress-test their supply chains virtually before a crisis hits reality.

Market Dynamics & Future:

Innovation: Growth is fueled by Generative AI Copilots, allowing supply chain managers to ask plain-language questions (e.g., “How will a hurricane in Florida impact our Q4 inventory?”) and receive instant, scenario-based answers and rerouting options.

Operational Shift: There is a decisive move toward “N-Tier Visibility,” where AI doesn’t just monitor direct suppliers (Tier 1) but uses web scraping and satellite data to monitor suppliers’ suppliers (Tier 2/3), identifying deep-lying risks.

Distribution: Cloud-Native Platforms are becoming the standard, allowing real-time data integration from thousands of disparate sources-shipping APIs, weather feeds, and news alerts-into a single “Control Tower.”

Future Outlook: The market will be defined by “Autonomous Negotiation,” where AI agents not only detect a shortage but automatically negotiate prices and book capacity with backup suppliers within pre-approved budget limits.

Click Here, Download a Free Sample Copy of this Market: https://marketresearchcorridor.com/request-sample/15837/

Drivers, Restraints, Challenges, and Opportunities Analysis:

Market Drivers:

Geopolitical Volatility: Trade wars, tariffs, and regional conflicts have made supply chains weaponized. Companies are adopting AI to dynamically re-shore or near-shore sourcing to safer regions in real-time.

Climate Change Impact: Extreme weather events (droughts in the Panama Canal, floods in manufacturing hubs) are disrupting logistics frequencies. AI weather prediction models are essential for rerouting cargo before it gets stuck.

Regulatory Compliance: New laws like the German Supply Chain Due Diligence Act and EU directives require companies to police their supply chains for forced labor and environmental damage. AI automates this massive auditing task.

Market Restraints:

Data Silos & Trust: Suppliers are often reluctant to share real-time inventory or capacity data with buyers due to fear of losing leverage. Without shared data, the AI is blind.

High Implementation Costs: Building a custom AI-driven control tower requires significant investment in data cleaning, cloud infrastructure, and talent, pricing out many mid-sized manufacturers.

Key Challenges:

The “Black Box” Problem: Supply chain managers are hesitant to trust an AI’s recommendation to reroute millions of dollars of cargo if they cannot understand why the AI made that decision (Explainability).

Data Quality: AI is only as good as the data it is fed. Inaccurate manual entries or outdated spreadsheets from suppliers can lead to disastrous automated decisions (“Garbage In, Garbage Out”).

Future Opportunities:

Scope 3 Emissions Tracking: Using AI to calculate the carbon footprint of every single shipment and supplier, helping companies meet Net Zero goals by optimizing routes for carbon, not just speed.

Cold Chain Optimization: Applying AI to pharma and food supply chains to predict temperature excursions and reduce the billions of dollars lost to spoilage annually.

Get to know more about this Report: https://marketresearchcorridor.com/schedule-the-call/

Market Segmentation:

By Component:

Solutions/Platforms (Control Towers, Risk Management Software)

Services (Consulting, Managed Supply Chain Services)

By Technology:

Machine Learning (ML)

Natural Language Processing (NLP)

Computer Vision (Warehouse/Inventory scanning)

Big Data Analytics

By Application:

Demand Forecasting & Planning

Supply Chain Risk Management (SCRM)

Inventory Optimization

Logistics & Transportation Management

Supplier Relationship Management

By Industry Vertical:

Manufacturing (Automotive, Aerospace)

Retail & Consumer Goods (CPG)

Healthcare & Pharmaceuticals

Food & Beverage

High Tech & Electronics

Region:

North America

U.S.

Canada

Mexico

Europe

U.K.

Germany

France

Italy

Spain

Rest of Europe

Asia Pacific

China

India

Japan

South Korea

Australia

Rest of Asia Pacific

South America

Brazil

Argentina

Rest of South America

Middle East and Africa

Saudi Arabia

UAE

Egypt

South Africa

Rest of Middle East and Africa

Competitive Landscape:

Top Tech & ERP Giants:

SAP SE (SAP IBP / Ariba)

Oracle Corporation (Fusion Cloud SCM)

Microsoft Corporation (Dynamics 365 Supply Chain)

Blue Yonder (Panasonic)

Kinaxis (RapidResponse)

Specialized Resilience & Risk Analytics:

Everstream Analytics

Project44 (Visibility)

Coupa Software (Llamasoft)

Interos (Multi-Tier Risk)

FourKites

Resilinc

Regional Trends:

The global market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

North America (Reshoring Hub): Dominates the market, driven by the massive push to “de-risk” supply chains from China. U.S. companies are heavily investing in AI to model the costs of moving manufacturing back to Mexico or the US (Nearshoring).

Europe (Sustainability Focus): Growth is shaped by the Green Deal and human rights legislation. European firms utilize AI primarily to trace raw materials back to the source to ensure no deforestation or child labor is involved, protecting brand reputation.

Asia-Pacific (Manufacturing Core): The fastest-growing region. As the “World’s Factory,” manufacturers in China, Vietnam, and India are adopting AI to optimize production schedules and navigate complex intra-Asian logistics routes during peak seasons.

Market Dynamics and Strategic Insights

Digital Twins as Stress Tests: The most strategic companies are building “Digital Twins” of their entire supply chain. They use AI to bombard this digital twin with simulated disasters (e.g., “What if the Suez Canal closes for a month?”) to identify weak points and build redundancy before a real crisis occurs.

From “Just-in-Time” to “Just-in-Sequence”: AI allows for a hybrid model. It maintains the efficiency of low inventory but uses predictive signals to stockpile critical components only when a disruption is highly probable.

GenAI for Contract Analysis: Legal teams are using Generative AI to scan thousands of supplier contracts instantly to find “Force Majeure” clauses or penalty terms during a disruption, speeding up legal decision-making.

The “China Plus One” Strategy: AI tools are essential for companies diversifying out of China. They use data to analyze labor costs, infrastructure stability, and shipping routes in alternative countries like Vietnam, India, or Thailand to find the optimal new manufacturing sites.

Get A Report Copy of this Market: https://marketresearchcorridor.com/request-sample/15837/

Contact Us:

Avinash Jain

Market Research Corridor

Phone : +1 518 250 6491

Email: Sales@marketresearchcorridor.com

Address: Market Research Corridor, B 502, Nisarg Pooja, Wakad, Pune, 411057, India

About Us:

Market Research Corridor is a global market research and management consulting firm serving businesses, non-profits, universities and government agencies. Our goal is to work with organizations to achieve continuous strategic improvement and achieve growth goals. Our industry research reports are designed to provide quantifiable information combined with key industry insights. We aim to provide our clients with the data they need to ensure sustainable organizational development.

This release was published on openPR.