The metal base copper clad laminate (MBCCL) market is poised for significant expansion as technological advancements and shifting industry demands drive growth. With applications spanning from electric vehicles to consumer electronics, this sector is witnessing increasing investment and innovation. Below is an overview of the market size, key players, emerging trends, and segmentation details that define the current landscape and future outlook of the MBCCL industry.

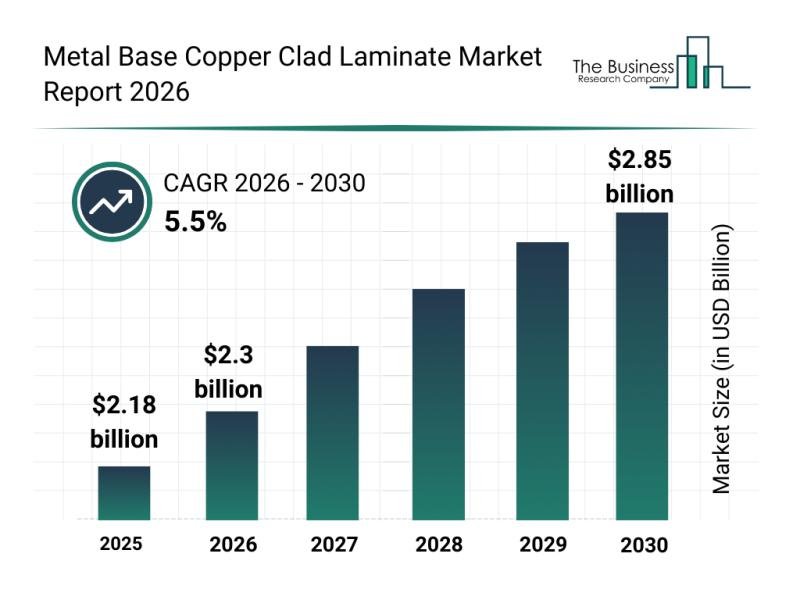

Projected Growth and Market Size of the Metal Base Copper Clad Laminate Sector

The metal base copper clad laminate market is anticipated to experience robust growth, reaching a valuation of $2.85 billion by 2030. This expansion reflects a compound annual growth rate (CAGR) of 5.5% throughout the forecast period. Several factors propel this upward trajectory, including the rising use of electronics in electric vehicles, the surge of renewable energy technologies such as solar electronics, and the growing adoption of Internet of Things (IoT) devices. Additionally, demand for compact consumer electronics and innovations in hybrid and specialty metal laminates contribute to market momentum. Leading trends expected to influence the market include advanced thermal management solutions, designs featuring high-density printed circuit boards (PCBs), lightweight yet durable substrates, laminates offering improved electrical conductivity, and highly customizable metal base laminates.

Download a free sample of the metal base copper clad laminate market report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=22054&type=smp

Key Drivers Behind the Expansion of the Metal Base Copper Clad Laminate Market

One of the main forces fueling growth in the MBCCL market is the increasing integration of electric vehicle electronics, which require reliable and efficient thermal management materials. As the automotive sector shifts toward electrification, the demand for metal base copper clad laminates that can support high-performance electronic components grows accordingly.

Another important driver is the rising use of renewable energy and solar electronics, which depend heavily on durable and thermally stable circuit substrates. The need for miniaturized consumer electronics and IoT devices also stimulates innovation in compact, efficient, and lightweight laminates. These drivers collectively push manufacturers to develop advanced metal base laminates tailored to evolving technological requirements.

Leading Market Participants in the Metal Base Copper Clad Laminate Industry

The competitive landscape of the metal base copper clad laminate market features prominent companies such as Panasonic Holdings Corporation, Nippon Steel Chemical & Materials Co. Ltd., 3M Company, AGC Inc., DuPont de Nemours Inc., Nan Ya Plastics Corp, Kingboard Holdings Ltd., Shengyi Technology (SYTECH), UBE Industries, Sumitomo Bakelite Co. Ltd., Taiwan Elite Material, ITEQ Corporation, Tenghui Electronics, Doosan Corporation Electro-Materials, Isola Group, Zhejiang Huazheng New Materials, Taiwan TAIFLEX Scientific, Chukoh Chemical Industry Co. Ltd., Goldenmax International Technology Ltd., Grace Electron Corp, Guangdong Chaohua Technology, Jinan Guoji Technology Co. Ltd., and RISHO KOGYO CO. LTD.

In a notable transaction in March 2023, MBK Partners, a private equity firm based in South Korea, acquired NexFlex for $403 million. This acquisition allows MBK Partners to capitalize on the growth potential of the flexible copper-clad laminate (FCCL) segment. NexFlex specializes in manufacturing flexible printed circuit boards (PCBs) and related electronic materials, strengthening MBK’s foothold in the flexible electronics market.

View the full metal base copper clad laminate market report:

https://www.thebusinessresearchcompany.com/report/metal-base-copper-clad-laminate-global-market-report

Innovations and Technological Trends Shaping the Metal Base Copper Clad Laminate Market

Industry leaders are advancing new types of copper-clad laminates with low thermal expansion properties to improve durability and meet the demands of next-generation electronic devices. These low thermal expansion laminates help reduce warping and maintain stability under high temperatures, which is crucial for high-performance applications.

For example, in February 2025, Japan’s Resonac Corporation introduced low thermal expansion copper-clad laminates designed specifically for next-generation semiconductor packaging. These laminates significantly reduce warpage, supporting larger package sizes over 100mm x 100mm. Testing showed they perform with four times the durability of traditional products during temperature cycling. This breakthrough was achieved through multiscale analysis, a computational science method used to optimize the design of laminate materials, and has been integrated into the company’s internal visualization system for physical properties.

Segment Breakdown and Market Forecasts for Metal Base Copper Clad Laminates

This report segments the metal base copper clad laminate market by several criteria:

1) Product Type: Including Iron-based Copper Clad Laminates, Silicon Steel Copper Clad Laminates, Aluminum Base Copper Clad Laminates, Copper-based Copper Clad Laminates, and other variants.

2) Processing Technology: Such as Layered Processing, Coating Technology, Laser Drilling, and Etching Technology.

3) Thickness: Categorized into Standard Thickness, Thick Cu Layer, and Ultra-Thin CCL.

4) Application Areas: Covering sectors like the automobile industry, aerospace and defense, consumer electronics, healthcare, industrial use, and other applications.

Further subcategories include:

– Iron-Based Copper Clad Laminates for power electronics, LED lighting, and automotive circuit boards.

– Silicon Steel Copper Clad Laminates used in high-frequency transformers, electromagnetic shielding, and industrial automation.

– Aluminum Base Copper Clad Laminates employed in LED heat dissipation boards, consumer electronics PCBs, and renewable energy systems.

– Copper-Based Copper Clad Laminates suitable for high-performance computing, aerospace and defense electronics, as well as RF and microwave applications.

– Other types encompass hybrid metal substrates, custom alloy laminates, and specialty industrial products.

Regional Market Dynamics and Growth Prospects

As of 2024, the North American region holds the largest share of the metal base copper clad laminate market. Nonetheless, the fastest growth rates are projected in the Asia-Pacific region due to expanding manufacturing capabilities and increasing demand from electronics and automotive sectors. The market analysis also accounts for key regions including Western Europe, Eastern Europe, South America, and the Middle East and Africa, offering a comprehensive global perspective.

Reach out to us:

The Business Research Company: https://www.thebusinessresearchcompany.com/,

Americas +1 310-496-7795,

Europe +44 7882 955267,

Asia & Others +44 7882 955267 & +91 8897263534,

Email us at info@tbrc.info.

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company,

Twitter: https://twitter.com/tbrc_info,

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Learn More About The Business Research Company

With over 17500+ reports from 27 industries covering 60+ geographies, The Business Research Company has built a reputation for offering comprehensive, data-rich research and insights. Armed with 1,500,000 datasets, the optimistic contribution of in-depth secondary research, and unique insights from industry leaders, you can get the information you need to stay ahead.Our flagship product, the Global Market Model (GMM), is a premier market intelligence platform delivering comprehensive and updated forecasts to support informed decision-making.

This release was published on openPR.