As automation deepens, production lines rely more than ever on stable network connectivity. This article outlines how industrial 5G and cloud-based management enable reliable device networking, remote operations, and real-time visibility-building a controllable, visible, and manageable foundation for smarter automated production lines.

CHANTILLY, VIRGINIA / ACCESS Newswire / January 26, 2026 / How Can Automated Production Lines Truly Move Toward Being “Controllable, Visible, and Remotely Manageable”?

In a growing number of manufacturing facilities, automation is no longer new.

PLCs, industrial robots, inspection equipment, and various sensors are now densely deployed across production lines, continuously driving improvements in efficiency.

At the same time, a frequently mentioned yet often underestimated issue is beginning to surface:

As equipment becomes increasingly automated, have production systems truly become more “controllable”?

Many manufacturers have found in practice that automation equipment itself is not the bottleneck. Instead, the network that connects these devices is often what determines whether operations remain stable.

1. Why Do Highly Automated Production Lines Fear “Unstable Networks” More?

In traditional production models, equipment relied primarily on local control, and networks mainly played a role in data aggregation or management support. However, as automation and flexibility deepen, networks have begun to directly participate in the “neural transmission” of production systems. Once network fluctuations occur, the impact is no longer limited to “data being seen later,” but may instead include:

Inability to return critical equipment status in real time

Failure of remote monitoring and scheduling

Inability to quickly locate faults, requiring personnel to go on-site

The higher the level of automation, the stronger the system’s dependence on stable connectivity. Therefore, when discussing network construction for smart factories, the focus is never simply “whether devices can connect,” but rather “whether the network can operate stably over the long term.”

2. What Problems Does 5G Solve in Smart Factories?

In one sentence, the value of 5G lies not merely in being “technologically advanced,” but in enabling production networks to achieve engineering-grade controllability.

In real production environments, the changes brought by 5G are mainly reflected in two aspects:

From “usable” to “predictable” real-time connectivity

Low latency and high concurrency ensure that critical production data can still be transmitted reliably in complex scenarios, no longer dependent on unpredictable network conditions.

From “localized access” to “production-line-level capacity”

Without large-scale modifications to existing production lines, 5G can reliably carry more devices and higher-density data communications, supporting the continuous upgrade of legacy production lines.

3. How Should a Practical 5G Smart Production Line Solution Be Built?

InHand Networks has introduced a 5G + Smart Factory Connectivity Solution that avoids unnecessary complexity and instead focuses on the operational determinism of production lines.

3.1 Production Line Side:

How can devices achieve “stable connectivity” rather than “barely connected”?

On automated production lines, the industrial-grade 5G IR624 router serves as the core on-site access node, connecting key units such as PLCs, robots, and inspection equipment into a unified network.

After devices connect via Ethernet or serial ports, the IR624 aggregates data and uploads it to the cloud through the 5G network.

The IR624 is not merely defined as an “internet access device,” but as a long-term operational node within the production line network. Its design priorities are therefore clear:

Industrial-grade reliability for complex on-site environments

Support for unified access of diverse device types

Capability for long-term continuous operation with reduced manual intervention

Once the IR624 is permanently deployed on-site, device connectivity no longer depends on “temporary solutions,” and the network becomes a trusted foundational capability of the production line.

3.2 Network Side:

How can a single network avoid bearing all the risk?

In highly automated production lines, network instability has already proven to be a systemic risk. The key on the network side is not simply “being connected,” but whether risks can be effectively isolated and controlled.

If all business data relies on a single communication path, any short-term fluctuation can propagate into the production system and affect continuous operation.

Therefore, on the network side, the industrial-grade 5G IR624 router, acting as the aggregation and egress node of the production line network, primarily assumes the role of link governance and risk control.

In actual operation, the device continuously monitors communication link status and automatically switches when link quality changes, preventing manual intervention and business interruption.

When the network has continuous monitoring and automatic failover capabilities, connectivity is no longer a recurring risk concern but becomes a stable and controllable operational safeguard within the production system.

3.3 Cloud Side:

Once on-site devices achieve stable connectivity, the real value begins to emerge.

The cloud platform is not intended to “replace on-site systems,” but to provide unified cross-line visibility and coordinated O&M.

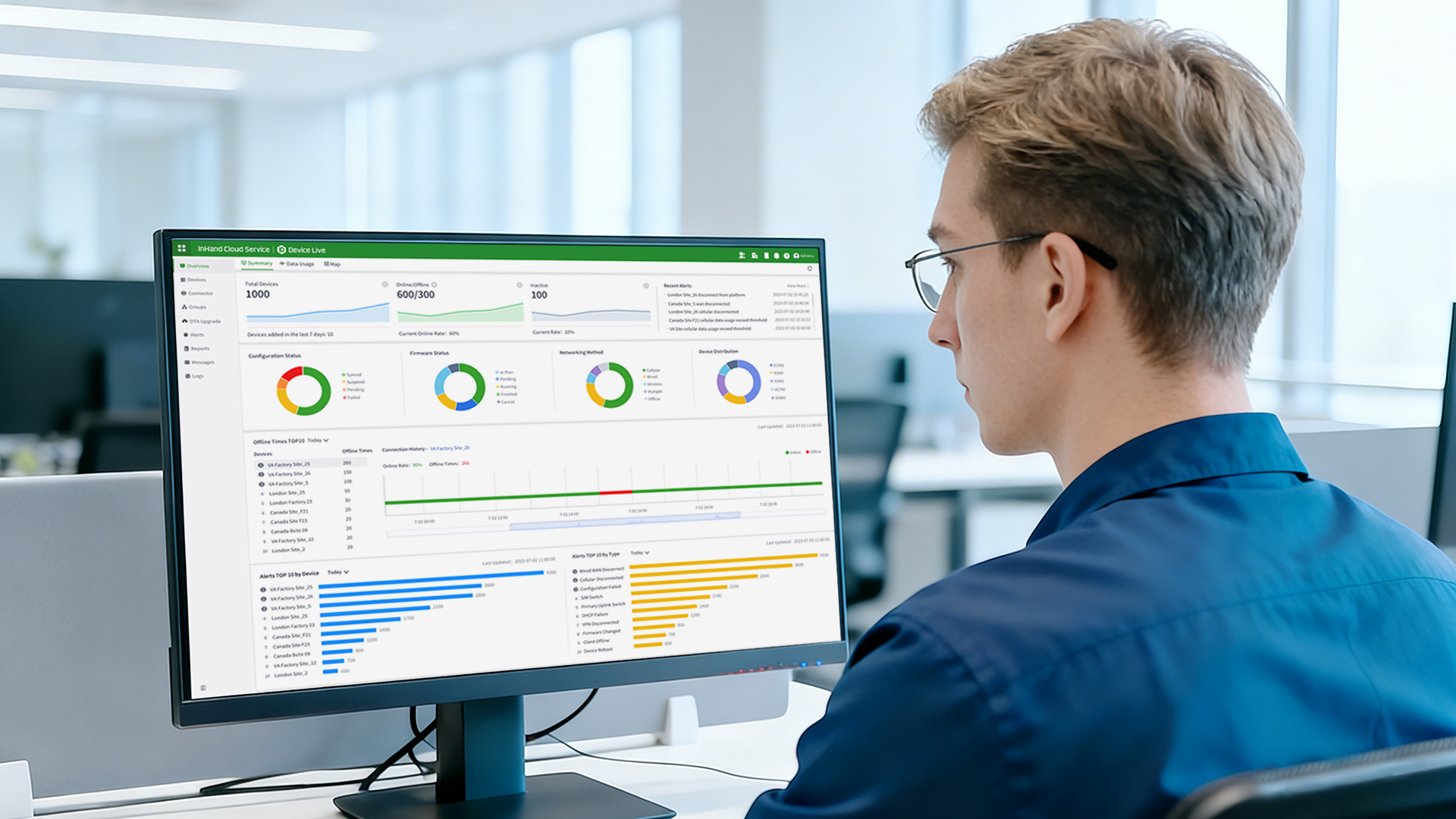

Industrial-grade 5G IR624 routers connect to the DeviceLive cloud management platform, enabling:

Centralized visualization of device online status, signal quality, and operational logs

Automatic alerts for abnormal events

Remote configuration, remote upgrades, and unified operations and maintenance

The O&M model thus shifts:

From “people watching the site” to “systems monitoring the network.”

4. What Changes Occur After Connectivity Becomes Truly Stable?

In practice, such solutions typically bring three significant improvements:

Production status becomes continuously and accurately visible

Whether devices are online and where network fluctuations occur no longer depends on experience-based judgment.

O&M shifts from passive response to proactive intervention

Issues are detected before they escalate, and many anomalies can be resolved without sending personnel on-site.

A foundation is established for more advanced digital and intelligent applications

Only when data is generated and transmitted continuously and reliably can applications such as MES, energy management, and predictive maintenance truly be implemented.

5. A Smart Factory Is Not an Instant “Intelligent Leap”

In industrial environments, truly effective digital transformation rarely begins with the most complex systems. Instead, it starts with the most fundamental and critical step: making production line connectivity stable, controllable, and manageable. Only when the network is no longer an uncertainty can intelligent capabilities truly grow.

In manufacturing, the value of any technology ultimately comes down to one question: does it make production more stable and management more assured? The significance of a 5G smart factory solution lies precisely in building a truly reliable connectivity foundation for automated production lines.

Learn more: https://www.inhand.com/en/products/industrial-routers/

About InHand Networks

InHand Networks is a leading IoT solutions provider founded in 2001, dedicated to driving digital transformation across industries and empowering customers to unlock their full potential and achieve accelerated growth.

We specialize in delivering industrial-grade connectivity solutions for diverse sectors, such as business networks, industrial IoT, digital energy, smart commerce, and mobility. Our comprehensive product portfolio and services cater to various applications worldwide, including smart manufacturing, smart grid, intelligent transportation, smart retail, etc. With a global footprint spanning over 60 countries, we serve customers in the United States, France, Germany, the United Kingdom, Italy, China, and beyond.

Learn more: http://www.inhand.com

Media Contact

Eleanor Chen

Marketing & Communications

[email protected]

SOURCE: InHand Networks