Micro Welding Service Market Overview:

The micro welding service market is growing rapidly due to increasing demand across various industries like electronics, medical devices, automotive, and aerospace. Micro welding is a specialized process that joins small components with precision, often using lasers, TIG (Tungsten Inert Gas), or electron beam welding technologies. As industries evolve toward miniaturization, the need for micro welding services has surged. These services enable manufacturers to work with tiny parts that require high accuracy, making them essential for producing high-quality, reliable products. The global trend toward automation and advanced manufacturing methods is also driving the adoption of micro welding services. Companies are focusing on improving welding efficiency, reducing costs, and ensuring accuracy in their production lines.

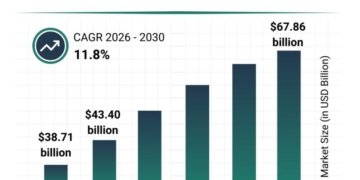

The Micro Welding Service Market size is expected to grow from 2.24(USD Billion) in 2024 to 3.5 (USD Billion) by 2032. The Micro Welding Service Market CAGR (growth rate) is expected to be around 5.71% during the forecast period (2024 – 2032).

Browse a Full Report (Including Full TOC, List of Tables & Figures, Chart) –

https://www.wiseguyreports.com/reports/micro-welding-service-market

Moreover, the rise in complex designs in medical devices and electronic gadgets has increased the importance of micro welding services. In medical technology, micro welding is used to manufacture devices such as pacemakers, surgical tools, and stents, where precision is critical. The same precision is required in automotive and aerospace industries where lightweight and durable materials are crucial. As a result, the micro welding service market is poised for significant growth in the coming years, with continuous technological advancements playing a vital role in shaping its future.

Market Segmentation:

The micro welding service market can be segmented based on application, technology, and end-user industries. In terms of application, micro welding services cater to various sectors including electronics, medical, automotive, aerospace, and jewelry manufacturing. Each industry has its unique welding requirements, driving the demand for specialized services. For example, the electronics sector requires fine welding for circuit boards and connectors, while the automotive industry focuses on micro welding for sensors and small components in electric vehicles.

When segmented by technology, the market is categorized into laser welding, TIG welding, and electron beam welding. Laser welding is gaining popularity due to its precision and ability to weld even the smallest of components without causing heat damage. TIG welding is widely used for metals such as titanium and stainless steel, offering precise control and high-quality welds. Electron beam welding, though less common, is utilized in highly specialized industries like aerospace, where materials require an extremely high level of precision and minimal distortion.

The market is also segmented based on end-user industries such as electronics, medical devices, automotive, aerospace, and others. The medical device and electronics industries currently dominate the market, largely because of their need for precision in welding tiny components. As technological advancements continue, the demand for micro welding in these industries is expected to grow further, leading to an increased adoption of specialized welding services.

Get a sample PDF of the report at –

https://www.wiseguyreports.com/sample-request?id=586493

Market Key Players:

Several key players dominate the micro welding service market, offering a wide range of welding solutions across various industries. Prominent companies include,

• Bystronic

• Universal Laser Systems

• Mitsubishi Electric

• RofinSinar Technologies

• TRUMPF

• Prima Industrie

• Lumentum Holdings

• Lasertec

• Mazak

• Coherent

These companies are known for providing advanced micro welding services, often tailored to the specific needs of different industries. They focus on delivering precision, quality, and innovation, making them preferred choices in the market.

Micro Weld, Inc. is a leading provider of precision welding services, offering both laser and TIG welding solutions. The company serves a variety of industries, including medical, aerospace, and electronics. Electron Beam Engineering, Inc. specializes in high-precision electron beam welding, catering to industries that require tight tolerances and high accuracy. LaserStar Technologies Corporation, on the other hand, focuses on laser welding solutions, which are widely used in industries like jewelry, medical devices, and electronics. Imperial Weld Ring Corporation provides welding services specifically for the aerospace and defense sectors, ensuring high-quality and reliable welding for critical components.

These companies, among others, continue to invest in research and development to improve welding technologies and expand their service offerings. They are also collaborating with clients to understand their unique welding needs and deliver customized solutions that enhance efficiency and product quality.

Recent Developments:

The micro welding service market has witnessed several recent developments, primarily driven by advancements in technology and the increasing demand from end-user industries. One significant development is the growing adoption of laser micro welding technology. Laser welding offers numerous benefits, such as minimal heat distortion, high precision, and the ability to weld delicate and small components. As a result, it has become a preferred choice in industries like electronics and medical devices, where accuracy is crucial.

Another notable development is the integration of automation and robotics in micro welding processes. Automation is playing an increasingly important role in manufacturing, as it enhances welding speed, reduces human error, and improves overall productivity. Robotic welding systems are being used in industries such as automotive and aerospace, where consistency and precision are key to producing high-quality components. Additionally, automation allows for better monitoring and control of the welding process, resulting in improved efficiency and reduced downtime.

The rise of 3D printing technology has also influenced the micro welding service market. 3D printing, combined with micro welding, is enabling manufacturers to produce complex parts with greater accuracy and efficiency. This is particularly beneficial for industries like aerospace and medical devices, where intricate designs and precision are essential. As 3D printing technology continues to advance, its integration with micro welding is expected to further boost market growth.

Market Dynamics:

Several factors are driving the growth of the micro welding service market. One of the key drivers is the increasing demand for miniaturization in industries like electronics, medical devices, and automotive. As products become smaller and more intricate, the need for precise welding techniques becomes more critical. Micro welding services provide the precision and control required to weld tiny components without compromising on quality, making them essential for manufacturers in these sectors.

Another factor contributing to market growth is the rising demand for lightweight materials in industries such as aerospace and automotive. Lightweight materials, such as aluminum and titanium, are increasingly being used to improve fuel efficiency and reduce emissions. However, these materials require specialized welding techniques, as they are more challenging to weld than traditional metals. Micro welding services, particularly laser welding and electron beam welding, are well-suited for working with lightweight materials, driving their adoption in these industries.

The growing trend of automation and smart manufacturing is also influencing the market dynamics. Manufacturers are increasingly adopting automated welding solutions to improve efficiency, reduce costs, and enhance product quality. The integration of robotics and artificial intelligence (AI) in welding processes is expected to further drive market growth by enabling more accurate and efficient welding operations.

Regional Analysis:

Geographically, the micro welding service market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. North America and Europe currently dominate the market, largely due to the presence of advanced manufacturing industries and a high demand for precision welding services. The United States, in particular, is a key market for micro welding services, with a strong presence in sectors such as medical devices, electronics, and aerospace. Europe, led by countries like Germany and the United Kingdom, is also a significant market, driven by the automotive and aerospace industries.

Asia-Pacific is expected to witness the fastest growth in the micro welding service market over the coming years. The region is home to some of the world’s largest electronics and automotive manufacturing industries, particularly in countries like China, Japan, and South Korea. The increasing demand for miniaturized electronic components and lightweight automotive parts is driving the adoption of micro welding services in the region. Additionally, the growing medical device industry in countries like India and China is further contributing to market growth.

Latin America and the Middle East and Africa are also emerging markets for micro welding services, with increasing industrialization and growing demand for advanced manufacturing technologies. While these regions are currently in the early stages of market development, they offer significant growth opportunities for companies providing micro welding services.

The micro welding service market is experiencing substantial growth, driven by technological advancements, increasing demand for miniaturization, and the rising adoption of lightweight materials. As industries continue to evolve, the need for precision welding services will only grow, creating new opportunities for market players across the globe.

Top Trending Reports:

• Security Risk Assessment Tool Market –

https://www.wiseguyreports.com/reports/security-risk-assessment-tool-market

• Restaurant Analytics Software Market –

https://www.wiseguyreports.com/reports/restaurant-analytics-software-market

• Pv Monitoring System Market –

https://www.wiseguyreports.com/reports/pv-monitoring-system-market

• Real Time Maps Market –

https://www.wiseguyreports.com/reports/real-time-maps-market

• Refrigerated Transport Services Market –

https://www.wiseguyreports.com/reports/refrigerated-transport-services-market

• Shampoo Testing Market –

https://www.wiseguyreports.com/reports/shampoo-testing-market

• Short Video App Market –

https://www.wiseguyreports.com/reports/short-video-app-market

• Silicone 3D Printing Service Market –

https://www.wiseguyreports.com/reports/silicone-3d-printing-service-market

• Resource Planning Tool Market –

https://www.wiseguyreports.com/reports/resource-planning-tool-market

• Residential Irrigation Solutions Market –

https://www.wiseguyreports.com/reports/residential-irrigation-solutions-market

About US:

Wise Guy Reports is pleased to introduce itself as a leading provider of insightful market research solutions that adapt to the ever-changing demands of businesses around the globe. By offering comprehensive market intelligence, our company enables corporate organizations to make informed choices, drive growth, and stay ahead in competitive markets.

We have a team of experts who blend industry knowledge and cutting-edge research methodologies to provide excellent insights across various sectors. Whether exploring new market opportunities, appraising consumer behavior, or evaluating competitive landscapes, we offer bespoke research solutions for your specific objectives.

At Wise Guy Reports, accuracy, reliability, and timeliness are our main priorities when preparing our deliverables. We want our clients to have information that can be used to act upon their strategic initiatives. We, therefore, aim to be your trustworthy partner within dynamic business settings through excellence and innovation.

Contact:

WISEGUY RESEARCH CONSULTANTS PVT LTD

Office No. 528, Amanora Chambers Pune – 411028

Maharashtra, India 411028

Sales: +91 20 6912 2998

This release was published on openPR.