According to a new study by DataHorizzon Research, the “Semiconductor Cleaning Solutions Market” is projected to grow at a CAGR of 6.6% from 2025 to 2033, driven by exponential growth in semiconductor manufacturing capacity, increasing complexity of chip architectures requiring advanced cleaning processes, and stringent contamination control requirements for next-generation electronic devices across automotive, consumer electronics, and telecommunications sectors. The market, currently valued at approximately $3.72 billion in 2024, is experiencing unprecedented expansion as semiconductor fabrication facilities implement cutting-edge cleaning technologies to achieve the ultra-pure processing environments essential for manufacturing advanced microprocessors, memory chips, and specialized semiconductors.

The convergence of artificial intelligence, Internet of Things applications, and 5G infrastructure deployment has intensified demand for high-performance semiconductors, necessitating sophisticated cleaning solutions that remove molecular-level contaminants while preserving delicate device structures. This comprehensive analysis reveals that the semiconductor cleaning solutions landscape is evolving from traditional wet chemical processes to innovative dry cleaning methodologies, plasma-based treatments, and environmentally sustainable formulations that meet both performance requirements and regulatory compliance standards for modern semiconductor manufacturing operations.

Get a free sample report: https://datahorizzonresearch.com/request-sample-pdf/semiconductor-cleaning-solutions-market-20088

Market Size & Insights

The semiconductor cleaning solutions market represents a critical enabler of the global electronics industry, encompassing specialized chemical formulations, equipment systems, and process technologies that ensure contamination-free semiconductor manufacturing environments. Current market dynamics reflect the industry’s transition toward smaller node geometries, three-dimensional device architectures, and advanced materials that demand unprecedented cleaning precision and selectivity. The market’s growth trajectory is intrinsically linked to semiconductor capital expenditure cycles, with major foundries and integrated device manufacturers investing billions in fab capacity expansion and technology upgrades.

Market segmentation reveals significant diversity in cleaning applications, ranging from pre-deposition surface preparation and post-etch residue removal to backend packaging and assembly processes. The increasing adoption of extreme ultraviolet lithography and atomic layer deposition techniques has created new cleaning challenges requiring innovative chemical solutions that can remove specific contaminants without damaging underlying materials. Advanced packaging technologies including through-silicon vias, wafer-level packaging, and heterogeneous integration demand specialized cleaning processes that accommodate complex geometries and multiple material interfaces.

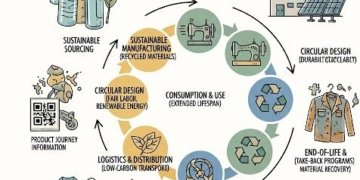

The market’s evolution is characterized by continuous innovation in chemical formulations that balance cleaning efficacy with environmental sustainability and worker safety considerations. Manufacturers are developing biodegradable cleaning agents, reducing volatile organic compound emissions, and implementing closed-loop recycling systems that minimize waste generation. Investment in research and development activities remains substantial as companies compete to develop breakthrough cleaning technologies that enable next-generation semiconductor devices while meeting increasingly stringent environmental regulations and sustainability targets across global manufacturing operations.

Market Growth

The semiconductor cleaning solutions market’s exceptional growth momentum stems from multiple technological and economic drivers reshaping the global electronics landscape. The proliferation of artificial intelligence applications, autonomous vehicles, and edge computing devices has created insatiable demand for high-performance semiconductors manufactured using advanced process nodes that require sophisticated cleaning solutions. Digital transformation initiatives across industries are driving semiconductor content increases in traditional products while creating entirely new device categories with specialized cleaning requirements.

The expansion of semiconductor manufacturing capacity in response to supply chain resilience initiatives has generated substantial demand for cleaning equipment and consumables. Government programs supporting domestic semiconductor production in key regions are accelerating fab construction and equipment procurement activities. The increasing complexity of semiconductor device structures, including advanced memory architectures and specialized processors for machine learning applications, necessitates continuous innovation in cleaning technologies to maintain manufacturing yields and product reliability standards.

Emerging Trends

The semiconductor cleaning solutions market is experiencing transformative trends that are fundamentally altering cleaning methodologies and equipment architectures. Artificial intelligence integration in cleaning process control represents a significant innovation frontier, with machine learning algorithms optimizing cleaning parameters, predicting maintenance requirements, and detecting contamination sources in real-time. Digital twin technologies are enabling virtual process optimization and predictive modeling that reduces development time for new cleaning processes.

Sustainable chemistry initiatives are driving the development of environmentally friendly cleaning formulations that replace traditional hazardous chemicals with biodegradable alternatives without compromising cleaning performance. Plasma-based dry cleaning technologies are gaining prominence for their ability to remove organic contaminants while minimizing chemical usage and waste generation. Additionally, the emergence of selective cleaning processes that target specific contaminants while preserving sensitive device materials is enabling more precise contamination control in advanced semiconductor manufacturing. Integration of real-time monitoring systems using advanced spectroscopy and particle detection technologies provides unprecedented visibility into cleaning effectiveness and process optimization opportunities.

Market Segments

By Product Type:

o Aqueous Cleaning Solutions

o Solvent-Based Cleaning Solutions

o Semi-Aqueous Cleaning Solutions

o Acid/Base Cleaning Solutions

o Others

By Wafer Size:

o ≤150 mm

o 200 mm

o 300 mm

o 300 mm

By Process Type:

o Front-End-of-Line (FEOL)

o Back-End-of-Line (BEOL)

By End-User:

o Integrated Device Manufacturers (IDMs)

o Foundries

o Outsourced Semiconductor Assembly and Test (OSAT)

o Others

By Regional:

o Asia-Pacific

o North America

o Europe

o Latin America

o Middle East and Africa

Top 10 Market Companies

• BASF SE

• DuPont de Nemours Inc.

• Merck KGaA

• Shin-Etsu Chemical Co. Ltd.

• Fujifilm Corporation

• Kanto Chemical Co. Inc.

• Solvay SA

• Honeywell International Inc.

• Cabot Microelectronics Corporation

• Avantor Inc.

Regional Insights

Asia-Pacific dominates the semiconductor cleaning solutions market, representing approximately 58% of global revenue, driven by the region’s concentration of semiconductor manufacturing facilities, substantial government investments in domestic chip production capabilities, and presence of major foundries and integrated device manufacturers. Taiwan, South Korea, and China lead regional demand with their advanced semiconductor ecosystems and aggressive capacity expansion plans supporting technological sovereignty initiatives. The region’s market leadership stems from favorable manufacturing costs, skilled workforce availability, and established supply chain networks that enable efficient delivery of cleaning solutions to production facilities. Japan contributes significantly through its advanced materials expertise and precision cleaning equipment manufacturing capabilities, while Southeast Asian countries demonstrate strong growth potential as semiconductor assembly and test operations expand to serve global markets.

Market Outlook

The semiconductor cleaning solutions market outlook through 2033 remains exceptionally positive, underpinned by continuous advancement in semiconductor technology, expanding application markets, and increasing performance requirements that demand sophisticated cleaning solutions. The market’s future development will be characterized by deeper integration of artificial intelligence and machine learning capabilities that enable autonomous process control, predictive maintenance, and real-time optimization of cleaning parameters. Advanced sensor technologies and Internet of Things connectivity will provide unprecedented visibility into cleaning process performance and contamination control effectiveness.

Sustainability initiatives will become increasingly central to market evolution, with emphasis on developing circular economy approaches that minimize waste generation, enable chemical recycling, and reduce environmental impact throughout the cleaning solution lifecycle. The development of bio-based cleaning formulations and renewable feedstock utilization will address regulatory pressures and corporate sustainability commitments while maintaining or improving cleaning performance standards. Innovation in packaging and delivery systems will reduce chemical consumption, improve handling safety, and enable more precise dosing control.

The emergence of new semiconductor materials including gallium arsenide, indium gallium arsenide, and silicon carbide will create specialized cleaning requirements that drive market expansion beyond traditional silicon-based applications. Quantum computing development and neuromorphic computing research will generate demand for ultra-precise cleaning solutions capable of working with exotic materials and maintaining atomic-level cleanliness standards. Advanced packaging technologies enabling chiplet integration and heterogeneous computing architectures will require innovative cleaning approaches that accommodate multiple materials and complex three-dimensional structures.

Market consolidation activities are expected to continue as major chemical companies acquire specialized cleaning solution providers to enhance their semiconductor market presence and technological capabilities. These strategic combinations typically result in accelerated innovation, expanded global distribution networks, and enhanced technical support capabilities that benefit semiconductor manufacturers through improved cleaning solutions and application expertise. Investment in manufacturing automation and quality control systems will ensure consistent product performance while reducing production costs and environmental impact.

The development of closed-loop cleaning systems that enable on-site chemical recycling and regeneration will transform market dynamics by reducing consumable costs and minimizing waste generation. Integration with fab-wide process control systems will enable holistic optimization of cleaning operations that considers interactions with other manufacturing processes and overall device yield objectives.

Contact:

Ajay N

Ph: +1-970-633-3460

Latest Reports:

Enamel Cups Market: https://datahorizzonresearch.com/enamel-cups-market-53730

Hair Removal Products Market: https://datahorizzonresearch.com/hair-removal-products-market-53731

Ride On Toys Market: https://datahorizzonresearch.com/ride-on-toys-market-53732

Booklet Maker Market: https://datahorizzonresearch.com/booklet-maker-market-53733

Company Name: DataHorizzon Research

Address: North Mason Street, Fort Collins,

Colorado, United States.

Mail: sales@datahorizzonresearch.com

DataHorizzon is a market research and advisory company that assists organizations across the globe in formulating growth strategies for changing business dynamics. Its offerings include consulting services across enterprises and business insights to make actionable decisions. DHR’s comprehensive research methodology for predicting long-term and sustainable trends in the market facilitates complex decisions for organizations.

This release was published on openPR.