Smart use of old data: COSCOM makes historical production data fit for modern production. (© COSCOM Computer GmbH)

Many manufacturing companies have a wealth of data that has been built up over the years – particularly in the area of tool management. In practice, however, the potential of this legacy data often remains untapped because it lies dormant in isolated solutions, is inconsistent or is difficult to access. With its ECO platform, COSCOM, the digitalization specialist for the store floor, offers a powerful solution for consolidating and processing this data and making it usable as a foundation for the next stage of digital manufacturing.

From brownfield to smart factory – sustainable and data-based

“Our task in current implementation projects is often to transfer fragmented tool data from systems such as CAD/CAM, tool presetting or machine controls into a consistent database,” explains Christian Erlinger, Managing Director of COSCOM Computer GmbH. The aim is not to replace existing IT investments and established brownfield structures, but to integrate them intelligently and develop them further.

COSCOM sees itself as a bridge builder between the past and the future – with in-depth expertise, a wide range of tried-and-tested tools and a deep understanding of heterogeneous data landscapes. “Our customers often lack a clear overview of the quality and potential of their legacy data. This is precisely where we come in with analysis, evaluation and targeted data blending,” says Erlinger.

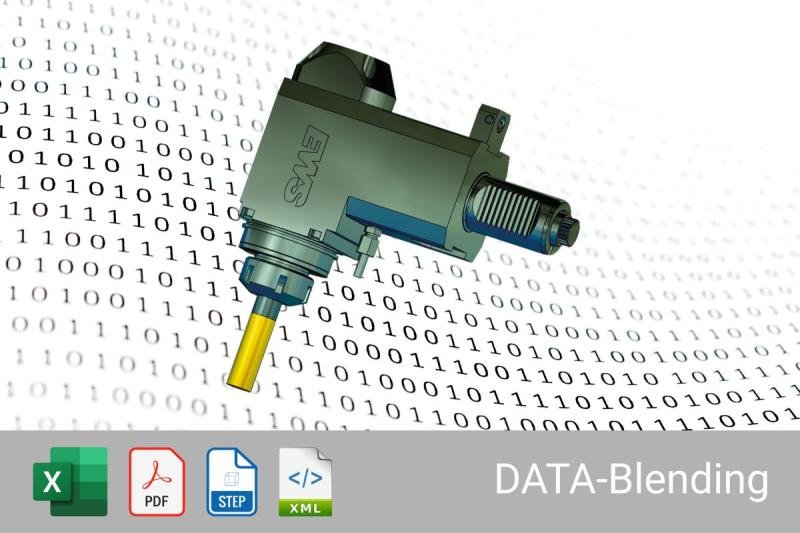

Efficient migration thanks to standard importer and data blending concept

With specially developed importers for common systems such as TDM Systems or Wintool, existing tool data can be seamlessly transferred to the COSCOM ECO platform. In addition, COSCOM’s own data blending concept enables a wide variety of data sources to be merged – from databases and Excel spreadsheets to XML files or ERP material master data. The result: a consolidated, structured data set that digitally supports all relevant store floor processes.

“In many cases, we discover additional, undocumented data sources – such as CAD derivatives on CNC machines or graphical tool data in CAM systems,” reports Erlinger. The data blending concept makes it possible to harness such information and transfer it into a holistic data structure – as a kind of fitness program for the database.

Multi-CAM-capable tool data: Standardized and usable across systems

The complexity of tool data is increasing in the CAD/CAM sector in particular – especially through the use of 3D graphics to calculate precise tool paths. With the COSCOM TCI concept (Tool Cooperation Interface), this data can be standardized and used across systems: One and the same digital tool twin can thus be used independently of the CAM system – including the system-specific tool parameters for collision-free path calculations.

Manufacturing reality requires multi-CAM strategies – COSCOM provides the platform for this

The trend towards individually configured machining centers means that manufacturing companies today often purchase specially adapted CAM systems with their machines. This often means that different CAM systems are used in parallel – the central tool data supply becomes a key function.

COSCOM counters this reality with a dedicated multi-CAM strategy based on the TCI concept. An example: A DMG lathe with 4-channel equipment is newly purchased. The CAM system already in operation does not support this machine and an additional CAM system specialized for this requirement is purchased. This is where the COSCOM concept comes into its own. The existing, centrally managed tool data in the COSCOM ECO platform can be immediately prepared for use in the new CAM system and put to use.

Further information can be found at

LEAD Industrie-Marketing GmbH

Hauptstraße 46

83684 Tegernsee

Germany

http://www.lead-industrie-marketing.de

Herr André Geßner

+49 8022 91 53 188

+49 8022 91 53 189

info@lead-industrie-marketing.de

About COSCOM Computer GmbH:

COSCOM – Software, consulting and projects – for digitization in machining production

COSCOM is a leading software system house that standardizes, networks and optimizes production data in the machining industry. The connection between the ERP system and production is a top priority. Projects in tool management, tool and data management, CAD/CAM and machine simulation as well as Infopoint / DNC networking are realized around the CNC machine. Competence in consulting and target-oriented project management are the basis for joint success – one contact, one responsibility, one successful project!

By networking the COSCOM software products, different, interface-free process solutions are created for networking all participants on the store floor. The main benefits for the user are a more efficient machining process with better product quality, greater adherence to deadlines and lower production costs. COSCOM offers everything from a single source – from software development, process consulting, sales and project management with implementation through to training/coaching, service and support.

COSCOM has been active on the market since 1978, making it one of the most experienced providers in the field of production automation and digitization in machining. Around 6,000 COSCOM solutions and around 25,000 machines and systems are currently networked with COSCOM systems throughout Europe. COSCOM as a partner means investment security, future security and innovation security for the customer.

This release was published on openPR.