Introduction:

The single-dose packaging market is experiencing robust growth, driven by a confluence of factors including increasing consumer demand for convenience, safety, and precise portion control. Single-dose packaging offers numerous advantages across various industries, providing pre-measured quantities of products, reducing waste, and minimizing the risk of contamination. This packaging format is particularly crucial in the pharmaceutical industry, where accurate dosage is paramount, and in the food and beverage sector, where it enhances portability and freshness. Technological advancements in packaging materials and machinery have further propelled market expansion, enabling the development of innovative single-dose solutions that cater to diverse product requirements and consumer preferences. The market’s growth is also linked to evolving lifestyles, with more consumers seeking on-the-go solutions and personalized products, which single-dose packaging effectively addresses.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/2467

Moreover, the single-dose packaging market plays a vital role in addressing global challenges related to healthcare and sustainability. In the healthcare sector, single-dose packaging ensures patient compliance by providing easy-to-use, pre-measured doses, which is particularly important for medications with strict dosage regimens. This packaging format also helps to reduce medication errors and improve overall treatment outcomes. From a sustainability perspective, single-dose packaging, while sometimes criticized for generating more packaging waste, can also contribute to waste reduction by minimizing product spoilage and overconsumption. Ongoing innovations in sustainable packaging materials, such as biodegradable and recyclable options, are further mitigating the environmental impact of single-dose packaging. The market’s ability to adapt to changing consumer needs and address industry-specific requirements, coupled with its role in promoting safety, convenience, and sustainability, positions it for continued growth in the coming years.

Request Discount: https://www.consegicbusinessintelligence.com/request-discount/2467

• Market Size:

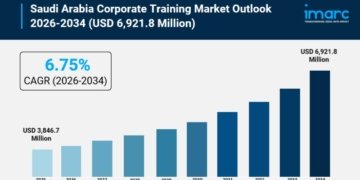

The global single-dose packaging market is projected to reach USD 92,243.07 Million by 2032, growing from USD 54,326.48 Million in 2025, at a Compound Annual Growth Rate (CAGR) of 7.6% from 2025 to 2032.

• Definition of Market:

The single-dose packaging market encompasses the production, distribution, and utilization of packaging solutions designed to contain a single, pre-measured quantity of a product. This packaging format is engineered to deliver a precise amount of a substance, whether it is a solid, liquid, powder, or gel, for immediate consumption or application. The market includes a wide array of packaging types, materials, and technologies, all focused on providing convenience, safety, and portion control. Key components of this market include the various packaging materials used, such as plastics, metals, glass, and paperboard; the different product forms that can be accommodated, including solids, liquids, powders, and gels; and the diverse end-user industries that utilize single-dose packaging, such as healthcare, food and beverage, cosmetics, homecare, and chemicals.

Several key terms are essential to understanding the single-dose packaging market. Unit dose packaging is a common synonym, particularly in the pharmaceutical industry, referring to the packaging of a single, prescribed dosage of medication. Blister packs are a type of single-dose packaging, often used for tablets and capsules, consisting of a pre-formed plastic cavity and a sealable backing material. Pouches are flexible packaging containers used for a variety of products, including liquids, powders, and gels. Vials are small containers, typically made of glass or plastic, used for liquid medications or other substances. Ampoules are small, sealed glass containers used to hold a single dose of a liquid, especially injectable medications. Sachets are small, sealed packets, often made of flexible materials, used for powders, granules, or liquids. Strip packs are a series of connected single-dose packages, often used for tablets or capsules. The market also involves various packaging technologies, such as form-fill-seal (FFS) machines, which automate the packaging process. Barrier properties of packaging materials, such as resistance to moisture, oxygen, and light, are crucial for maintaining product integrity.

Buy Now: https://www.consegicbusinessintelligence.com/secure-checkout/2467

• Market Scope and Overview:

The single-dose packaging market encompasses a broad range of packaging solutions designed to contain individual servings or applications of various products across diverse industries globally. The market’s scope includes the materials used in single-dose packaging, such as plastics, metals, glass, and paperboard; the technologies employed in the packaging process, including automated filling and sealing machinery; and the various product forms that can be accommodated, such as solids, liquids, powders, and gels. The end-user industries served by this market are extensive, spanning healthcare (pharmaceuticals, medical devices), food and beverage, cosmetics, homecare, and chemicals. The market addresses the need for convenience, safety, portion control, and product integrity across these sectors. It caters to a wide range of consumers, from those seeking on-the-go solutions to patients requiring precise medication dosages.

The single-dose packaging market plays a crucial role in the larger context of global trends such as increasing consumer demand for convenience and portability, the growing emphasis on product safety and hygiene, and the rising awareness of sustainable packaging practices. In the healthcare sector, single-dose packaging is vital for ensuring patient compliance and reducing medication errors, contributing to improved treatment outcomes and public health. In the food and beverage industry, it enhances the convenience of consuming products on the move, reduces food waste by providing appropriate portion sizes, and maintains product freshness. The cosmetics industry utilizes single-dose packaging to offer trial sizes, personalized products, and hygienic application. The homecare and chemical sectors benefit from single-dose packaging by providing safety and preventing misuse or overexposure to potentially hazardous substances. The market’s ability to provide solutions that meet these diverse needs across various industries makes it an integral part of modern consumer culture and a key enabler of efficient and safe product delivery. The ongoing development of innovative packaging materials and technologies, coupled with the increasing focus on sustainability, will continue to shape the market’s growth and its contribution to global trends.

Top Key Players & Market Share Insights:

The single dose packaging market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global single-dose packaging market. Key players in the single dose packaging industry include –

• Gerresheimer AG (Germany)

• Schott AG (Germany)

• Berry Global, Inc. (United States)

• AptarGroup, Inc. (United States)

• Amcor plc (Australia)

• Nipro Corporation (Japan)

• Unit Pack Company Inc. (United States)

• West Pharmaceutical Services, Inc. (United States)

• Catalent Inc. (United States)

• Adelphi Healthcare Packaging (United Kingdom)

Access Full Report: https://www.consegicbusinessintelligence.com/single-dose-packaging-market

Market Segmentation:

The single-dose packaging market can be segmented based on several key factors, including material type, product form, and end-user industry. Each segment caters to specific requirements across various sectors and contributes uniquely to the overall market growth. Understanding these segments is crucial for stakeholders to identify market opportunities and tailor their offerings to meet evolving industry demands.

By Material Type:

• Plastic: Plastic is the most widely used material in single-dose packaging due to its versatility, cost-effectiveness, and excellent barrier properties. Various types of plastics, such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), are used to create a wide range of single-dose formats, including pouches, sachets, and blister packs.

• Metal: Metal, particularly aluminum, is used for single-dose packaging that requires high barrier properties and product protection. Applications include pharmaceutical blister packs, small tubes for creams and ointments, and packaging for certain food and beverage products.

• Glass: Glass offers excellent barrier properties, chemical inertness, and a premium aesthetic, making it suitable for single-dose packaging in the pharmaceutical, cosmetic, and fragrance industries. Ampoules and small vials are common single-dose glass formats.

• Paper & Paperboard: Paper and paperboard are used for single-dose packaging where sustainability and recyclability are key considerations. Applications include sachets for dry powders, small cartons for single-serve food items, and certain cosmetic samples.

By Product Form:

• Solid: Single-dose packaging for solid products includes tablets, capsules, pills, and powders. Blister packs, strip packs, and small sachets are commonly used formats, particularly in the pharmaceutical and nutraceutical industries.

• Liquid: Single-dose packaging for liquids includes solutions, suspensions, and emulsions. Pouches, vials, and ampoules are used to contain liquid medications, beverages, and cosmetic products.

• Powder: Single-dose packaging for powders includes dry medications, food additives, and cosmetic powders. Sachets and small pouches are commonly used to provide convenient and pre-measured portions.

• Gel: Single-dose packaging for gels includes topical medications, personal care products, and certain food items. Small tubes, pouches, and blister packs are used to dispense gels in a controlled and hygienic manner.

By End-User Industry:

• Healthcare: The healthcare industry is a major user of single-dose packaging, driven by the need for accurate dosage, patient compliance, and product safety. Applications include pharmaceuticals, medical devices, and diagnostic products.

• Food & Beverage: Single-dose packaging in the food and beverage industry provides convenience, portion control, and freshness for products such as condiments, sauces, coffee, tea, and ready-to-drink beverages.

• Cosmetics: The cosmetics industry uses single-dose packaging for samples, trial sizes, and personalized products, offering convenience and hygiene for items such as creams, lotions, and serums.

• Homecare: Single-dose packaging in the homecare sector provides safety and convenience for products such as cleaning agents, detergents, and disinfectants, preventing misuse and ensuring proper application.

• Chemical: The chemical industry uses single-dose packaging for hazardous or sensitive materials, ensuring safety during handling, transportation, and application, and preventing overexposure or contamination.

Market Drivers:

• Increasing Demand for Convenience and Portability: Consumers are increasingly seeking on-the-go solutions and convenient packaging formats that fit their busy lifestyles, driving the demand for single-dose packaging across various industries.

• Rising Focus on Product Safety and Hygiene: Single-dose packaging minimizes the risk of contamination and ensures product integrity, which is particularly crucial in the healthcare, food and beverage, and cosmetics industries.

• Growing Emphasis on Accurate Dosage and Portion Control: In the pharmaceutical industry, single-dose packaging ensures patient compliance and reduces medication errors. In the food and beverage industry, it helps consumers manage portion sizes and reduce food waste.

• Technological Advancements in Packaging Materials and Machinery: Innovations in packaging materials, such as high-barrier films and sustainable plastics, and advancements in automated packaging machinery are enabling the development of more efficient and cost-effective single-dose solutions.

• Increasing Geriatric Population and Self-Administration of Medications: The growing elderly population and the trend towards self-administration of medications are driving the demand for easy-to-use, single-dose packaging formats that improve patient compliance.

• Growth of E-commerce and Online Sales: Single-dose packaging provides product protection and convenience for products sold online, reducing the risk of damage during transit and enhancing the consumer experience.

• Rising Demand for Sustainable Packaging Solutions: The increasing awareness of environmental concerns is driving the demand for single-dose packaging made from recyclable, biodegradable, or compostable materials.

Market Key Trends:

• Development of Sustainable Single-Dose Packaging: Increasing focus on creating single-dose packaging solutions from eco-friendly materials, such as bioplastics, recycled plastics, and paper-based materials, to reduce environmental impact.

• Integration of Smart Packaging Technologies: Incorporation of features like QR codes, NFC tags, and sensors into single-dose packaging to enhance product traceability, provide consumer information, and improve supply chain management.

• Personalized and Customized Packaging Solutions: Growing trend towards single-dose packaging that caters to individual consumer needs and preferences, such as customized dosages, personalized product formulations, and on-demand packaging.

• Advancements in Barrier Properties and Product Protection: Development of single-dose packaging materials with enhanced barrier properties to protect products from moisture, oxygen, light, and other environmental factors, extending shelf life and maintaining product integrity.

• Increasing Adoption of Aseptic Packaging Techniques: Rising use of aseptic packaging processes to produce sterile single-dose packaging for pharmaceuticals, food, and beverages, ensuring product safety and extending shelf life without the need for preservatives.

• Miniaturization and Space Optimization: Trend towards smaller and more compact single-dose packaging formats to reduce material usage, minimize waste, and improve portability, particularly in the cosmetics and pharmaceutical industries.

• Focus on Child-Resistant and Senior-Friendly Packaging: Development of single-dose packaging solutions that are difficult for children to open but easy for seniors to use, addressing safety concerns and improving usability for specific consumer groups.

Market Opportunities:

• Expansion in Emerging Economies: Significant growth potential in developing countries with increasing consumer spending, rising healthcare awareness, and growing adoption of modern packaging solutions.

• Development of Innovative Packaging Formats: Opportunities to create new and unique single-dose packaging formats that offer enhanced convenience, functionality, and aesthetic appeal.

• Integration with Digital Health and Telemedicine: Potential to combine single-dose packaging with digital health platforms and telemedicine services to improve medication adherence and patient outcomes.

• Focus on Sustainable Packaging Solutions: Growing demand for eco-friendly single-dose packaging presents opportunities for manufacturers to innovate in sustainable materials and production processes.

• Customization and Personalization: Offering customized single-dose packaging solutions that cater to individual consumer needs and preferences can create a competitive advantage and enhance brand loyalty.

• Collaboration with Pharmaceutical and Food Companies: Partnerships with pharmaceutical and food companies to develop single-dose packaging solutions for new and innovative products can drive market growth.

• Development of Advanced Barrier Materials: Opportunities to create single-dose packaging with superior barrier properties to protect sensitive products and extend shelf life.

Market Restraints:

• Higher Packaging Costs Compared to Bulk Packaging: Single-dose packaging generally requires more materials and complex manufacturing processes, leading to higher costs compared to traditional bulk packaging.

• Environmental Concerns Related to Increased Packaging Waste: Single-dose packaging can generate more packaging waste per unit of product compared to bulk packaging, raising environmental concerns and increasing pressure for sustainable solutions.

• Limitations in Packaging Certain Product Types: Some products, particularly those with very large volumes or specific handling requirements, may not be suitable for single-dose packaging.

• Regulatory Challenges and Varying Standards: Different regions and industries have varying regulations and standards for single-dose packaging, which can create challenges for manufacturers operating in multiple markets.

• Consumer Perception and Resistance to Certain Materials: Some consumers may have negative perceptions about certain packaging materials, such as plastics, which can limit the adoption of single-dose packaging in some applications.

• Technical Challenges in Packaging Some Products: Packaging certain products in single-dose formats, such as highly viscous liquids or delicate powders, can present technical challenges related to filling, sealing, and product stability.

• Competition from Alternative Packaging Solutions: Single-dose packaging faces competition from other packaging formats, such as multi-dose packaging, portion-controlled packaging, and bulk packaging, which may be more suitable or cost-effective for certain products.

• Market Challenges:

The single-dose packaging market, while experiencing robust growth, faces several significant challenges that could impact its future development. One of the most pressing challenges is the environmental impact of increased packaging waste. Single-dose packaging, by its nature, generates more packaging material per unit of product compared to bulk packaging. This increased volume of waste raises concerns about landfill capacity, plastic pollution, and the overall sustainability of packaging practices. Addressing this challenge requires a multi-faceted approach, including the development of more sustainable packaging materials, such as biodegradable and recyclable options, the implementation of effective waste management and recycling systems, and the promotion of consumer awareness about responsible packaging disposal.

Another significant challenge is the higher cost associated with single-dose packaging compared to bulk packaging. The production of single-dose formats often involves more complex manufacturing processes, requires more materials, and may necessitate specialized equipment, all of which contribute to higher packaging costs. These increased costs can be a barrier for both manufacturers and consumers, particularly in price-sensitive markets or for products with low profit margins. Overcoming this challenge requires innovations in packaging technologies, the development of more cost-effective materials, and the optimization of supply chain processes to reduce production expenses and make single-dose packaging more economically viable.

Ensuring product compatibility and stability within single-dose packaging formats presents another key challenge. Different products have unique requirements in terms of barrier properties, chemical compatibility, and protection from environmental factors such as moisture, oxygen, and light. Developing single-dose packaging solutions that can effectively protect a wide range of products while maintaining their integrity and extending their shelf life requires advanced materials science, precise engineering, and rigorous testing. This challenge is particularly critical in the pharmaceutical and food and beverage industries, where product safety and efficacy are paramount.

Furthermore, meeting diverse regulatory requirements across different regions and industries poses a significant challenge for manufacturers of single-dose packaging. Packaging regulations vary widely in terms of labeling, materials, safety standards, and environmental compliance. Navigating these complex and often conflicting regulations can be a costly and time-consuming process for companies operating in global markets. Harmonization of packaging standards, improved regulatory clarity, and the development of flexible packaging solutions that can comply with multiple regulations are needed to address this challenge.

Finally, addressing consumer perceptions and preferences regarding single-dose packaging is crucial. While many consumers appreciate the convenience and hygiene of single-dose formats, some may have concerns about the environmental impact or may prefer larger, more economical packaging options. Educating consumers about the benefits of single-dose packaging, such as portion control, reduced waste, and improved product safety, and offering a range of packaging options to cater to diverse preferences can help to overcome this challenge and promote wider acceptance of single-dose solutions.

• Market Regional Analysis:

The single-dose packaging market exhibits diverse dynamics across different regions, influenced by varying consumer preferences, regulatory landscapes, economic development, and industry-specific needs. Asia-Pacific is currently the largest and fastest-growing market, driven by the region’s large and growing population, rising disposable incomes, and increasing demand for convenience and on-the-go solutions. Countries like China, India, and Japan are witnessing significant growth in the adoption of single-dose packaging across various sectors, including healthcare, food and beverage, and cosmetics. The region’s expanding pharmaceutical industry and the increasing prevalence of chronic diseases are also driving the demand for single-dose medication packaging.

North America is a mature market with a well-established single-dose packaging industry, particularly in the pharmaceutical and food and beverage sectors. The United States and Canada have stringent regulations regarding product safety and labeling, which drive the demand for high-quality, single-dose packaging solutions. The region’s aging population and the increasing prevalence of chronic diseases are also contributing to the growth of the single-dose medication packaging market. Europe is another significant market, characterized by a strong emphasis on sustainability and stringent environmental regulations. The European Union’s focus on reducing packaging waste and promoting recycling is driving the demand for eco-friendly single-dose packaging solutions, such as those made from biodegradable or recyclable materials. The region’s pharmaceutical and cosmetics industries are also major users of single-dose packaging.

Latin America is an emerging market with significant growth potential, driven by the region’s expanding middle class, increasing urbanization, and rising demand for packaged goods. Countries like Brazil and Mexico are witnessing growth in the adoption of single-dose packaging across various sectors, including food and beverage, pharmaceuticals, and cosmetics. The region’s growing healthcare sector and increasing awareness of product safety are also contributing to market expansion. The Middle East and Africa region is also experiencing growth in the single-dose packaging market, driven by the region’s increasing population, rising disposable incomes, and changing consumer lifestyles. The demand for convenience and on-the-go solutions is driving the adoption of single-dose packaging in the food and beverage, cosmetics, and pharmaceutical sectors. The region’s hot climate and the need for product protection are also factors influencing market dynamics.

Each region presents unique opportunities and challenges for the single-dose packaging market. Factors such as consumer preferences, regulatory requirements, economic conditions, and industry-specific needs influence the adoption of single-dose packaging solutions. Market players need to consider these regional variations when developing their strategies and product offerings to cater to the diverse needs of consumers and industries across the globe. The development of customized packaging solutions, tailored to the specific requirements of each region, is crucial for maximizing market penetration and driving sustainable growth.

• Frequently Asked Questions:

1) What is the projected growth rate of the single-dose packaging market?

The single-dose packaging market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.6% from 2025 to 2032.

2) What are the key trends in the single-dose packaging market?

Key trends include the development of sustainable single-dose packaging, the integration of smart packaging technologies, the rise of personalized and customized packaging solutions, and advancements in barrier properties and product protection.

3) What are the major end-user industries for single-dose packaging?

The major end-user industries include healthcare, food & beverage, cosmetics, homecare, and chemicals.

4) What is the market size of Single dose packaging market in 2025 and 2032?

The global single-dose packaging market is projected to reach USD 92,243.07 Million by 2032, growing from USD 54,326.48 Million in 2025.

Contact us:

Consegic Business intelligence Pvt Ltd

B 202 , 2nd Floor, Ujwal Serene, Baner Road, Baner, Pune, Maharashtra – 411045.

(US) (505) 715-4344

info@consegicbusinessintelligence.com

About us:

At Consegic Business Intelligence Pvt. Ltd., we empower businesses with actionable insights and innovative market intelligence solutions. Our tailored research and data-driven strategies help organizations navigate complex industry landscapes and make confident decisions.

Specializing in market research, consulting, and competitive analysis, we deliver precise and holistic insights across global and regional markets. Our client-focused approach ensures customized solutions that drive growth and foster informed decision-making.

This release was published on openPR.