Aromatic Polyester Polyols Market Introduction

The Aromatic Polyester Polyols Market focuses on a specific type of polyol that incorporates aromatic structures within its chemical backbone, typically derived from recycled polyethylene terephthalate (rPET) or phthalic anhydride and its derivatives. Polyols are organic compounds with multiple hydroxyl (-OH) groups and serve as crucial building blocks in the production of polyurethane polymers. Aromatic polyester polyols are primarily used in the manufacturing of rigid polyurethane foams, which find extensive applications in construction (insulation panels, spray foam), furniture (rigid foam components), and industrial packaging.

These polyols often offer advantages such as enhanced rigidity, improved fire retardancy, and cost-effectiveness, particularly when derived from recycled PET, contributing to waste reduction and circular economy initiatives. The market is influenced by the demand for rigid polyurethane foams in various end-use industries, the availability and cost of raw materials (including rPET and aromatic acids), and the increasing focus on sustainability and the use of recycled content in polymer production. The Aromatic Polyester Polyols Market involves chemical manufacturers producing these specialized polyols and polyurethane foam manufacturers as the primary consumers.

• Aromatic Polyester Polyols Market Size:

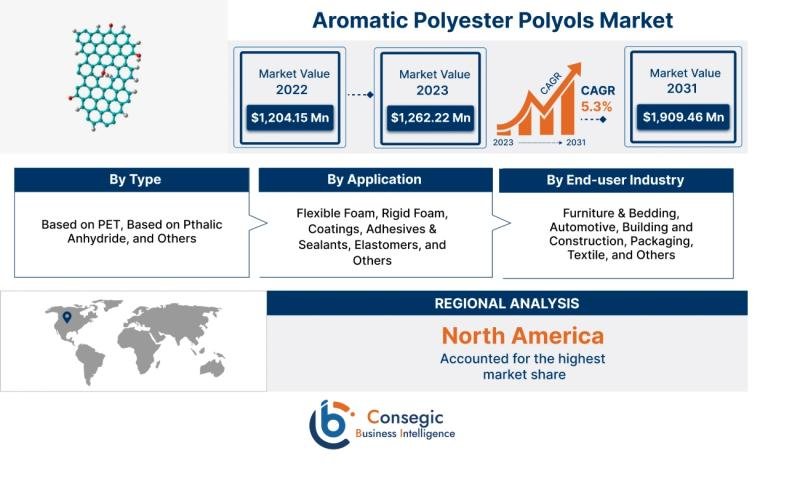

Consegic Business Intelligence analyzes that the aromatic polyester polyols market is growing with a CAGR of 5.3% during the forecast period (2023-2031). The market accounted for USD 1,204.15 million in 2022 and USD 1,262.22 million in 2023, and the market is projected to be valued at USD 1,909.46 Million by 2031.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/1352

• Aromatic Polyester Polyols Market Major Driving Factors and Opportunities

1) Several key factors are driving the growth and creating significant opportunities within the Aromatic Polyester Polyols Market. The increasing demand for rigid polyurethane foams across various end-use industries is a primary driver. The construction sector, in particular, utilizes rigid polyurethane foams extensively for thermal insulation in walls, roofs, and floors due to their excellent insulation properties. The growing emphasis on energy efficiency in buildings and stringent building codes are further boosting this demand. Similarly, the demand from the furniture and industrial packaging sectors for rigid foam components contributes to market growth.

2) The growing focus on sustainability and the circular economy is a major opportunity for aromatic polyester polyols derived from recycled PET (rPET). Utilizing rPET as a feedstock not only reduces waste destined for landfills but also offers a cost-effective alternative to virgin polyol production. Increasing environmental regulations and consumer preferences for sustainable products are expected to drive the adoption of rPET-based aromatic polyester polyols.

3) The cost-effectiveness of aromatic polyester polyols, especially those based on rPET, compared to some other types of polyols, makes them an attractive option for manufacturers of rigid polyurethane foams, particularly in price-sensitive applications. The availability of rPET as a relatively inexpensive feedstock can provide a competitive advantage.

4) Technological advancements in the production of aromatic polyester polyols are improving their quality and expanding their application scope. Innovations in processing techniques and catalyst systems are leading to polyols with tailored properties and enhanced performance in rigid foam formulations.

5) Government initiatives and regulations promoting the use of recycled materials in manufacturing are also creating a favorable environment for the growth of rPET-based aromatic polyester polyols. Incentives and mandates for incorporating recycled content can further drive their adoption in polyurethane applications.

Request Discount: https://www.consegicbusinessintelligence.com/request-discount/1352

• Aromatic Polyester Polyols Market Scope

The scope of the Aromatic Polyester Polyols Market encompasses the production, distribution, and application of polyols containing aromatic structures, primarily used in rigid polyurethane foams. This includes:

1) Types of Aromatic Polyester Polyols: Covering those derived from recycled PET (rPET-based polyols) and those synthesized from virgin aromatic monomers like phthalic anhydride.

2) Feedstock Sources: Including the collection, processing, and depolymerization of rPET, as well as the production of virgin aromatic acids and anhydrides.

3) Manufacturing Processes: Encompassing the chemical reactions and processing steps involved in synthesizing aromatic polyester polyols.

4) Distribution Channels: Involving chemical manufacturers, distributors, and suppliers that facilitate the sale and delivery of these polyols to polyurethane foam producers.

5) End-Use Applications: Primarily the manufacturing of rigid polyurethane foams used in construction insulation, furniture components, industrial packaging, refrigeration, and other specialized applications.

6) Performance Characteristics: Focusing on properties such as rigidity, fire retardancy, insulation value, and compatibility with polyurethane foam formulations.

Buy Now: https://www.consegicbusinessintelligence.com/secure-checkout/1352

• Converter Modules Market Key Market Trends

As consistently noted, “Converter Modules” typically refer to power conversion circuits and are not directly related to the Aromatic Polyester Polyols Market. Therefore, the key market trends for converter modules (e.g., increasing demand for high efficiency, integration of wide-bandgap semiconductors, miniaturization) are not directly applicable to the production, distribution, or use of aromatic polyester polyols. However, it is important to recognize that the chemical industry, including facilities producing polyols and polyurethane foams, relies on stable and efficient electrical power for its operations.

The efficiency and reliability of power supplies and related electrical components, where converter modules play a role, are indirectly important for the cost-effectiveness and sustainability of these processes. Trends in energy efficiency and robust power solutions in the broader chemical and industrial sectors could have an indirect positive impact on the overall economics of aromatic polyester polyol production and polyurethane foam manufacturing.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/1352

• Aromatic Polyester Polyols Market Key Players

The Aromatic Polyester Polyols Market includes several key manufacturers that specialize in producing these polyols, often with a focus on sustainability and utilizing recycled PET. Some of the key players in this market include:

1) Stepan Company

2) BASF SE

3) XUCHUAN CHEMICAL(SUZHOU) CO., LTD

4) Arkema

5) Evonik Industries AG

6) Purinova SP

7) Synthesia Technology Group

8) Emery Oleochemicals

9) Huntsman International LLC

10) Coim Group

The aromatic polyester polyols market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks.

• Aromatic Polyester Polyols Market Segmentation

The Aromatic Polyester Polyols Market can be segmented based on several factors:

1) By Type :

Based on PET

Based on Pthalic Anhydride

Others

2) By Application:

Flexible Foam

Rigid Foam

Coatings

Adhesives & Sealants

Elastomers

Others

3) By End-user Industry:

Furniture & Bedding

Automotive

Building and Construction

Packaging

Textile

Others

This segmentation helps to understand the different types of aromatic polyester polyols, their applications in various rigid polyurethane foam markets, and the regional dynamics influencing their demand.

• Aromatic Polyester Polyols Market Opportunities and Challenges

The Aromatic Polyester Polyols Market presents significant opportunities for future growth and expansion:

1) Growing demand for sustainable and recycled materials: The increasing global focus on circular economy initiatives and waste reduction is driving the adoption of rPET-based aromatic polyester polyols.

2) Stringent energy efficiency regulations in buildings: The need for high-performance thermal insulation in construction to meet energy efficiency standards will continue to drive the demand for rigid polyurethane foams made with aromatic polyester polyols.

3) Cost advantages of rPET-based polyols: Utilizing recycled PET can offer a more cost-effective feedstock compared to virgin monomers, making these polyols attractive in price-sensitive applications.

4) Technological advancements in rPET recycling and polyol production: Innovations in chemical recycling technologies and polyol synthesis are improving the quality and expanding the applicability of rPET-based aromatic polyester polyols.

5) Increasing awareness of the environmental benefits of using recycled content: Consumer preferences and corporate sustainability goals are favoring products made with recycled materials.

However, the market also faces certain challenges:

1) Fluctuations in the supply and quality of rPET feedstock: The availability and consistency of quality of recycled PET can be a concern for manufacturers relying on this feedstock.

2) Performance limitations compared to some virgin polyols: In certain high-performance applications, rPET-based polyols might face challenges in meeting specific property requirements compared to polyols made from virgin monomers.

3) Price volatility of virgin aromatic monomers: The cost of phthalic anhydride and other virgin aromatic feedstocks can fluctuate based on crude oil prices and market dynamics.

4) Competition from other types of polyols: Aromatic polyester polyols compete with other polyols, such as polyether polyols and bio-based polyols, in the rigid polyurethane foam market.

5) Regulatory hurdles and standards for recycled materials: Varying regulations and standards regarding the use of recycled content in different applications can create challenges for market adoption.

6) Ensuring consistent quality and performance of rPET-based polyols: Maintaining consistent quality and performance in polyols derived from variable sources of recycled PET requires robust quality control measures.

• Aromatic Polyester Polyols Market Regional Analysis

The Aromatic Polyester Polyols Market exhibits regional variations based on the level of construction activity, the development of the recycling infrastructure, and the emphasis on sustainability:

1) Asia Pacific: A major and rapidly growing market due to significant construction activities, particularly in China and India, and increasing government focus on energy efficiency in buildings. The development of PET recycling infrastructure is also advancing in the region.

2) Europe: A significant market with a strong emphasis on sustainability and circular economy initiatives. Well-established PET recycling infrastructure and stringent building energy efficiency regulations drive the demand for rPET-based aromatic polyester polyols.

3) North America: A mature market with substantial demand for rigid polyurethane foams in construction and industrial applications. The focus on recycling and sustainable materials is increasing.

4) Latin America: A growing market with increasing construction activities and a developing focus on recycling.

5) Middle East & Africa: The market is developing, driven by construction growth and increasing awareness of energy efficiency.

The adoption of rPET-based aromatic polyester polyols is generally higher in regions with well-established recycling infrastructure and strong sustainability initiatives, such as Europe.

• Converter Modules Market Recent Developments

As has been the consistent case, “Converter Modules” are related to power electronics and are not directly relevant to the Aromatic Polyester Polyols Market. Therefore, recent developments in that field (e.g., advancements in high-efficiency power converters for industrial automation, the integration of digital control in DC-DC converters, and the development of robust power supplies for harsh environments) are not directly applicable to the production, distribution, or application of aromatic polyester polyols.

However, if we consider recent developments within the chemical manufacturing and polymer industries that might indirectly impact the aromatic polyester polyols market, we could observe trends such as:

Advancements in chemical recycling technologies for PET: New and more efficient methods for depolymerizing PET waste into its constituent monomers or oligomers are improving the quality and availability of rPET feedstock for polyol production.

Development of new catalysts and processes for polyol synthesis: Innovations in catalytic systems and reaction processes are leading to aromatic polyester polyols with tailored properties and improved production efficiency.

Contact us:

Consegic Business intelligence Pvt Ltd

B 202 , 2nd Floor, Ujwal Serene, Baner Road, Baner, Pune, Maharashtra – 411045.

(US) (505) 715-4344

info@consegicbusinessintelligence.com

About us:

At Consegic Business Intelligence Pvt. Ltd., we empower businesses with actionable insights and innovative market intelligence solutions. Our tailored research and data-driven strategies help organizations navigate complex industry landscapes and make confident decisions.

Specializing in market research, consulting, and competitive analysis, we deliver precise and holistic insights across global and regional markets. Our client-focused approach ensures customized solutions that drive growth and foster informed decision-making.

This release was published on openPR.