Isoprene Monomer Market Introduction

The Isoprene Monomer Market focuses on the production, distribution, and application of isoprene (C5H), a colorless, volatile liquid hydrocarbon. Isoprene is a naturally occurring compound produced by many plants and animals, and it serves as a crucial building block in the synthesis of various polymers, most notably synthetic rubber (polyisoprene). The primary source of isoprene for industrial use is as a byproduct of ethylene and propylene production during the thermal cracking of petroleum naphtha. However, efforts are also underway to produce isoprene from renewable resources.

The main application of isoprene monomer is in the manufacturing of synthetic polyisoprene rubber, which closely mimics natural rubber in its properties and is used in tires, mechanical goods, adhesives, and other rubber-based products. The market is influenced by the demand from the automotive industry (for tires), the growth of other rubber-consuming sectors, and the availability and cost of crude oil and natural gas, which are the primary feedstocks for its production. The Isoprene Monomer Market involves petrochemical companies producing isoprene, chemical distributors facilitating its sale, and polymer manufacturers as the primary end-users.

Isoprene Monomer Market Introduction:

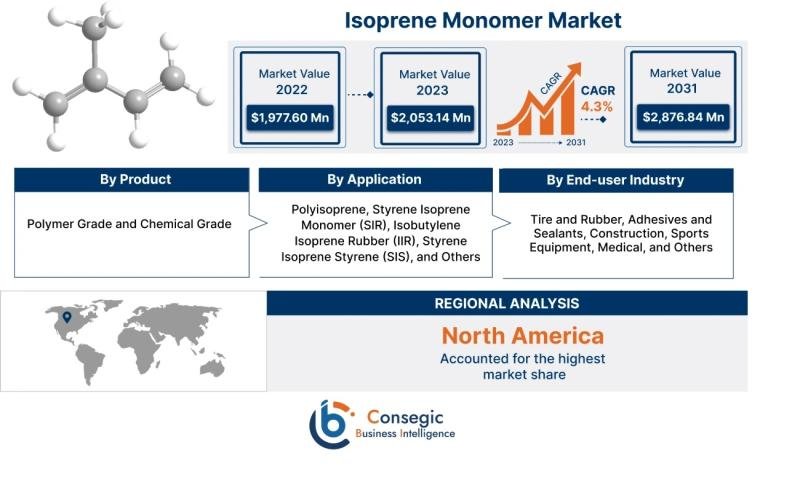

Consegic Business Intelligence analyzes that the isoprene monomer market size is growing with a CAGR of 4.3% during the forecast period (2023-2031). The market accounted for USD 1,977.60 million in 2022 and USD 2,053.14 million in 2023, and the market is projected to be valued at USD 2,876.84 Million by 2031.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/1353

• Isoprene Monomer Market Major Driving Factors and Opportunities

Several key factors are driving the growth and creating significant opportunities within the Isoprene Monomer Market. The increasing demand for tires from the automotive industry is a primary driver. As global vehicle production and sales continue to rise, particularly in developing economies, the need for tires, a major application of polyisoprene rubber, is also increasing. This directly fuels the demand for isoprene monomer.

The growing demand for synthetic rubber in various non-tire applications also contributes significantly to the market. Polyisoprene rubber is used in a wide range of industrial and consumer products, including mechanical goods, adhesives, footwear, and medical devices. The expansion of these sectors drives further consumption of isoprene monomer.

The limited and fluctuating supply of natural rubber creates opportunities for synthetic polyisoprene as a viable and sometimes more stable alternative. Factors such as weather conditions, disease outbreaks affecting rubber trees, and geopolitical issues can impact the supply and price of natural rubber, making synthetic alternatives more attractive.

Request Discount: https://www.consegicbusinessintelligence.com/request-discount/1353

• Isoprene Monomer Market Scope

1) The scope of the Isoprene Monomer Market encompasses the production, distribution, and application of isoprene (C5H). This includes:

2) Production Sources: Covering isoprene derived as a byproduct of ethylene and propylene production (C5 stream) and emerging bio-based production technologies.

3) Manufacturing Processes: Including the various chemical processes involved in extracting and purifying isoprene from the C5 stream and the biochemical pathways for bio-based production.

4) Distribution Channels: Involving petrochemical companies, chemical distributors, and transportation networks that facilitate the supply of isoprene to end-users.

5) End-User Industries: Primarily the synthetic rubber (polyisoprene) manufacturing sector, which then supplies to tire manufacturers and producers of other rubber goods.

6) Grades and Specifications: Different purity levels and specifications of isoprene monomer required for various applications.

7) Storage and Handling: The safe and regulated storage and transportation of this flammable and volatile chemical.

The market scope extends geographically across all regions with significant petrochemical production and rubber manufacturing industries. It also includes ongoing research and development efforts focused on improving production efficiency, developing bio-based isoprene, and exploring new applications for isoprene-based polymers.

Buy Now: https://www.consegicbusinessintelligence.com/secure-checkout/1353

• Converter Modules Market Key Market Trends

As consistently noted, “Converter Modules” typically refer to power conversion circuits and are not directly related to the Isoprene Monomer Market. Therefore, the key market trends for converter modules (e.g., increasing demand for high efficiency, integration of wide-bandgap semiconductors, miniaturization) are not directly applicable to the production, distribution, or use of isoprene monomer.

However, it is important to recognize that the petrochemical industry, including facilities producing isoprene, relies heavily on stable and efficient electrical power for its operations. The efficiency and reliability of power supplies and related electrical components, where converter modules play a role, are indirectly important for the cost-effectiveness and sustainability of isoprene production. Trends in energy efficiency and robust power solutions in the broader chemical and industrial sectors could have an indirect positive impact on the overall economics of isoprene monomer production.

Get a sample report: https://www.consegicbusinessintelligence.com/request-sample/1353

• Isoprene Monomer Market Key Players

The Isoprene Monomer Market is dominated by major petrochemical companies that produce isoprene as a byproduct of their olefin production. Some of the key players in this market include:

1) Braskem

2) China Petrochemical Corporation

3) Shandong Yuhuang Chemical Co.

4) Shell

5) ZEON CORPORATION

6) Goodyear International Corporation Co. Ltd.

7) LOTTE Chemical CORPORATION

8) LyondellBasell Industries Holdings B.V.

9) Mitsui & Co. Benelux S. A./N. V.

The market is relatively concentrated, with a few large petrochemical companies holding a significant share of the global production capacity. The competitive landscape is influenced by factors such as feedstock availability, production efficiency, and the integrated nature of petrochemical complexes.

• Isoprene Monomer Market Segmentation

The Isoprene Monomer Market can be segmented based on several factors:

Based on the Product:

1) Polymer Grade

2) Chemical Grade

Based on the Application:

1) Polyisoprene, Styrene Isoprene Monomer (SIR)

2) Isobutylene Isoprene Rubber (IIR)

3) Styrene Isoprene Styrene (SIS)

4) Others

Based on the End-user Industry:

1) Tire and Rubber

2) Adhesives and Sealants

3) Construction

4) Sports Equipment

5) Medical

6) Others

This segmentation provides a detailed understanding of the different production methods, applications, and regional consumption patterns within the Isoprene Monomer Market.

• Isoprene Monomer Market Opportunities and Challenges

The Isoprene Monomer Market presents several opportunities for future growth and development:

1) Increasing demand for high-performance tires: The growing automotive sector and the demand for tires with improved fuel efficiency and durability are driving the need for high-quality polyisoprene rubber, thus boosting isoprene demand.

2) Growth in non-tire rubber applications: The expanding use of synthetic rubber in various industrial and consumer goods provides a steady demand for isoprene monomer.

3) Potential of bio-based isoprene production: Advances in biotechnology could lead to commercially viable and sustainable production of isoprene from renewable resources, reducing reliance on fossil fuels and attracting environmentally conscious consumers.

4) Development of new isoprene-based polymers and materials: Ongoing research into novel polymers and chemicals derived from isoprene could open up new application areas and market opportunities.

5) Strategic importance in reducing dependence on natural rubber: Fluctuations in the supply and price of natural rubber make synthetic polyisoprene and, consequently, isoprene monomer, a strategically important material.

• However, the market also faces certain challenges:

1) Dependence on crude oil prices: The primary production route for isoprene is linked to the petrochemical industry, making its supply and price susceptible to fluctuations in crude oil and natural gas prices.

2) Competition from other synthetic rubbers: Other synthetic rubbers like styrene-butadiene rubber (SBR) and butadiene rubber (BR) can be used as substitutes in some applications, posing a competitive challenge.

3) Environmental concerns related to petrochemical production: The environmental impact of petroleum-based isoprene production is a growing concern, driving the need for more sustainable alternatives.

4) Technical challenges in bio-based isoprene production: Scaling up bio-based isoprene production to commercially viable levels and achieving cost competitiveness with petroleum-based isoprene remains a significant challenge.

5) Volatility in automotive demand: Fluctuations in the automotive industry, a major end-user of tires, can directly impact the demand for isoprene monomer.

6) Stringent environmental regulations: Increasing environmental regulations on emissions and waste from petrochemical plants can increase production costs.

Addressing these challenges through innovation in production technologies, the development of sustainable alternatives, and strategic market positioning will be crucial for the long-term growth and stability of the Isoprene Monomer Market.

• Isoprene Monomer Market Regional Analysis

The Isoprene Monomer Market exhibits regional variations based on the presence of petrochemical industries and rubber manufacturing sectors:

1) Asia Pacific: This is the largest consuming region for isoprene monomer due to the significant tire manufacturing industry in countries like China, Japan, South Korea, and India. The presence of major petrochemical producers in this region also contributes to the market.

2) North America: A significant market with a well-established automotive and rubber industry. The region also has substantial petrochemical production capacity.

3) Europe: A mature market with a strong presence of both petrochemical producers and rubber product manufacturers. Environmental regulations and the focus on sustainable materials are influential factors.

4) Latin America: A growing market, particularly in countries like Brazil, with a developing automotive and rubber industry and some petrochemical production.

5) Middle East & Africa: The market is growing, driven by increasing automotive production and the expansion of petrochemical industries in the region.

The demand for isoprene monomer is closely tied to the growth of the automotive and rubber industries in each region, as well as the regional petrochemical production capacities. Asia Pacific is expected to remain the dominant consuming region due to its large manufacturing base.

• Converter Modules Market Recent Developments

As has been consistently noted, “Converter Modules” are related to power electronics and are not directly relevant to the Isoprene Monomer Market. Therefore, recent developments in that field (e.g., advancements in high-power density converters for industrial applications, the integration of digital control in DC-DC converters, and the development of robust power supplies for harsh environments) are not directly applicable to the production, distribution, or application of isoprene monomer.

However, if we consider recent developments within the petrochemical and chemical manufacturing sectors that might indirectly impact the isoprene monomer market, we could observe trends such as:

Integration of advanced process optimization technologies: Petrochemical companies are increasingly using digital tools and automation to improve the efficiency and yield of their production processes, including isoprene extraction.

Focus on reducing environmental footprint: Efforts to minimize emissions and waste from petrochemical plants are driving investments in cleaner production technologies.

Contact us:

Consegic Business intelligence Pvt Ltd

B 202 , 2nd Floor, Ujwal Serene, Baner Road, Baner, Pune, Maharashtra – 411045.

(US) (505) 715-4344

info@consegicbusinessintelligence.com

About us:

At Consegic Business Intelligence Pvt. Ltd., we empower businesses with actionable insights and innovative market intelligence solutions. Our tailored research and data-driven strategies help organizations navigate complex industry landscapes and make confident decisions.

Specializing in market research, consulting, and competitive analysis, we deliver precise and holistic insights across global and regional markets. Our client-focused approach ensures customized solutions that drive growth and foster informed decision-making.

This release was published on openPR.