The requirement for reliable and accurate quality control has heightened due to rapid technological evolution. Conventional metrology methods have failed to meet the manufacturing sector’s demands. Hence, 3D metrology has now emerged as a prominent solution to streamline the operations in the production process. It designs a 3D simulation of the object being measured and then creates a color map. This data is then stored to produce new components to enhance every consecutive part and maintain precision.

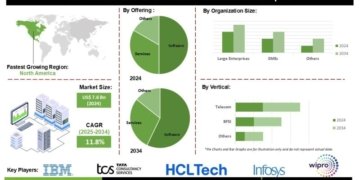

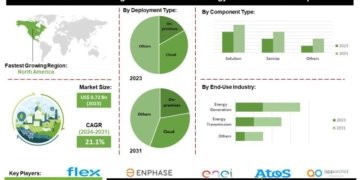

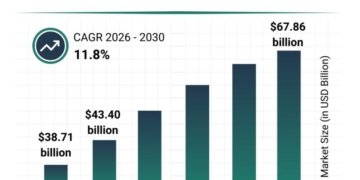

The expansion of the automotive industry worldwide and the rise in focus on quality control in goods manufacturing have contributed to the growth of the 3D metrology market. Additionally, the increase in demand for high productivity by electronics manufacturers fuels the expansion of the industry. Furthermore, advancements in computer vision and 3D scanning are making measurement tools affordable and accessible to a wide range of users.

Get a PDF brochure for Industrial Insights and Business Intelligence @ https://www.alliedmarketresearch.com/request-sample/A11620

Prominent use cases of 3D metrology technology

When it comes to advanced parts made up of exotic materials, replacement can be expensive. With advances in 3D metrology, it has become possible to repair these parts affordably. The data on damaged areas is first collected to create material for the existing part, guiding the 3D printer to repair the irregular surface of the damaged section. Conventional metrology techniques fail to repair damage on intricate surfaces because it requires too much time to map relevant points.

A quick scan develops highly precise surface measurements that can be used for repair. Once the part gets scanned, repaired, and finalized, it is again analyzed to decide whether it is within the regulated tolerances.

Additionally, in the healthcare sector, 3D metrology is utilized to design human physiology and anatomy including tissue, organs, and bones. It supports implant design and installation, guides surgery, and aids in treatment planning and diagnosis.

Get Customized Reports with your Requirements: https://www.alliedmarketresearch.com/request-for-customization/A11620

Innovations optimizing the efficiency of metrology tools

Technological innovations such as ML and AI are transforming 3D metrology systems. Smart algorithms improve the assessment of large datasets developed by systems to enable accurate and faster measurements. These technologies also perform predictive maintenance to lower downtime and boost system performance.

Another emerging shift in the industry is the development of handheld and portable devices. These devices allow operators to handle metrology tools with ease. The portability of these devices enables rapid measurements and facilitates on-site inspections in diverse environments with high productivity.

Evolving sensor technology has also optimized the potential of 3D metrology tools. Advancements like structured light systems and laser scanners have accelerated the speed and accuracy of the measurement process. These sensors collect minute details with high accuracy, which promotes superior inspection in quality control and manufacturing processes.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/A11620

Flexxbotics announced Robot compatibility with 3D measurement solutions

Flexxbotics announced advanced robotic machine tending in October 2024. It is perfect for quality checking connectivity with LMI Technologies’ 3D scanning and inspection systems. Organizations can use robot-based manufacturing with Flexxbotics and LMI Technologies to maintain Six Sigma consistency and closed-loop quality in unattended operations.

The FlexxCORE technology assists the robots in communicating with LMI equipment. They receive feedback on the basis of automated inspection outcomes. This allows real-time alterations to CNC programs for process control.

Access the Full Report @ https://www.alliedmarketresearch.com/3d-metrology-market-A11620

RSSL’s New 3D Imaging and Metrology Lab

A food and life science contract research organization, RSSL, opened a new lab offering 3D imaging and metrology operations in September 2024. This new laboratory delivers a unique blend of microscopy, spectroscopy techniques, and micro-CT, that offers clients holistic and comprehensive assessments of their products. These methodologies can be used for R&D regulatory compliance and quality control.

To conclude, 3D metrology has emerged as a prominent solution to streamline the operations in the production process. Technological advancements such as AI and ML are enhancing the efficiency and accuracy of tools used for mapping. These technologies also perform predictive maintenance to lower downtime and boost system performance.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises and medium and small businesses with unmatched quality of “Market Research Reports Insights” and “Business Intelligence Solutions.” AMR aims to provide business insights and consulting to assist its clients in making strategic business decisions and achieving sustainable growth in their respective market domains.

Contact Us:

David Correa

1209 Orange Street,

Corporation Trust Center,

Wilmington, New Castle,

Delaware 19801 USA.

Int’l: +1-503-894-6022

Toll Free: +1-800-792-5285

Fax: +1-800-792-5285

help@alliedmarketresearch.com

This release was published on openPR.