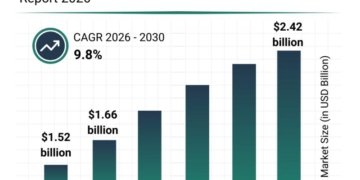

The Plastic Injection Molding Machine Market was valued at USD 12.88 billion in 2024 and is expected to reach USD 16.26 billion by 2033, growing at a CAGR of 6.4% during the forecast period from 2025 to 2033. Market growth is driven by rising demand for lightweight and durable plastic components across automotive, packaging, consumer goods, electronics, and healthcare industries. Increasing industrial automation, rapid urbanization, and expanding manufacturing activities in emerging economies are further supporting the adoption of advanced injection molding machinery worldwide.

Technological advancements such as energy efficient electric injection molding machines, integration of smart sensors, and real time process monitoring are transforming production efficiency and precision. The growing focus on sustainable manufacturing, including recyclable polymers and reduced material waste, is encouraging manufacturers to upgrade to next generation molding systems. In addition, rising investments in high speed, multi material, and precision micro molding technologies are strengthening long term growth prospects for the global plastic injection molding machine market.

Get a Free Sample PDF Of This Report (Get Higher Priority for Corporate Email ID):- https://www.datamintelligence.com/download-sample/plastic-injection-molding-machine-market?sai-v

Plastic Injection Molding Machine Market refers to the industry focused on the manufacturing, sale, and technological advancement of machines that produce plastic components by injecting molten material into molds for use across automotive, packaging, electronics, healthcare, and consumer goods applications.

Key Developments

✅ January 2026: In Europe (Germany), Arburg GmbH + Co KG unveiled the latest generation of its ALLROUNDER injection molding series with enhanced energy efficiency, smart production monitoring, and improved precision control tailored for automotive and medical plastics manufacturing.

✅ December 2025: In Japan, Nissei Plastic Industrial Co., Ltd. launched a new high-speed electric injection molding machine designed to boost productivity and precision in electronics and consumer goods applications, supporting the region’s advanced manufacturing needs.

✅ November 2025: Across North America, Milacron LLC expanded its large-tonnage hydraulic injection molding machine lineup with upgraded automation compatibility, targeting heavy automotive component and industrial plastics production segments.

✅ October 2025: In Asia Pacific (China and South Korea), Chen Hsong Holdings Ltd introduced a series of hybrid injection molding machines that combine servo-hydraulic and electric technologies to improve cycle times and reduce energy consumption for various molding applications.

✅ September 2025: In North America and Europe, Husky Injection Molding Systems Ltd reported broader adoption of its advanced molding solutions with integrated IoT and predictive maintenance features to support smart factory and Industry 4.0 initiatives.

✅ August 2025: In global markets, KraussMaffei Group announced strategic enhancements to its GX series injection molding machines focused on precision micro-molding and sustainable operation for packaging, medical, and consumer electronics industries.

Key Players

Haitian International Holdings Limited | Sumitomo Heavy Industries, Ltd. | The Japan Steel Works, Ltd. | Chen Hsong Holdings Limited | ENGEL AUSTRIA GmbH | ARBURG GmbH + Co. KG | Nissei Plastic Industrial Co. Ltd. | Coperion GmbH | Husky Technologies | KraussMaffei Group GmbH | Others

Buy Now & Unlock 360° Market Intelligence:https://www.datamintelligence.com/buy-now-page?report=plastic-injection-molding-machine-market?sai-v

(Single User Report: USD 4350 & One Year Database Subscription: USD 12K

Market Drivers

Rising Demand from Packaging and Consumer Goods: Increasing production of plastic packaging, containers, and household products is driving machine adoption.

Growth in Automotive and Electric Vehicle Components: Lightweight plastic parts for interiors, exteriors, and battery systems are boosting injection molding demand.

Expansion of Medical Device Manufacturing: High precision molding for syringes, diagnostic components, and disposable medical products is accelerating market growth.

Advancements in Energy Efficient and Electric Machines: Shift toward all electric and hybrid molding systems is improving productivity while reducing power consumption.

Increasing Industrial Automation and Smart Manufacturing: Integration with robotics, sensors, and digital monitoring is enhancing production efficiency and quality control.

Industry Developments

Launch of High Speed and Precision Molding Systems: Manufacturers are introducing machines with faster cycle times, improved accuracy, and reduced material waste.

Adoption of Industry 4.0 and IoT Connectivity: Smart injection molding machines now enable real time monitoring, predictive maintenance, and remote operation.

Growth of Multi Material and Micro Injection Technologies: Advanced systems support complex product designs and miniaturized component production.

Strategic Partnerships and Capacity Expansion: Companies are investing in new facilities and collaborations to meet rising global plastics demand.

Focus on Sustainable Processing Solutions: Development of machines compatible with recycled and bio based plastics is gaining momentum.

Regional Insights

Asia Pacific – Holds 43% share: Strong manufacturing base, expanding packaging industry, and rapid industrialization drive regional dominance.

Europe – Holds 23% share: Advanced automotive sector, sustainability regulations, and precision engineering expertise support steady growth.

North America – Holds 22% share: High automation adoption, medical device production, and technological innovation sustain demand.

Latin America – Holds 7% share: Growing consumer goods manufacturing and industrial development create emerging opportunities.

Middle East and Africa – Holds 5% share: Increasing investment in manufacturing infrastructure and packaging industries contributes to gradual expansion.

Speak to Our Analyst and Get Customization in the report as per your requirements: https://www.datamintelligence.com/customize/plastic-injection-molding-machine-market?sai-v

Key Segments

By Machine Type

Hydraulic machines hold a significant share due to their high clamping force capability, suitability for large and complex molded components, and cost effectiveness in heavy duty industrial applications. All electric machines are witnessing rapid adoption driven by superior energy efficiency, precision control, lower maintenance requirements, and suitability for cleanroom and high accuracy manufacturing environments. Hybrid machines combine the advantages of hydraulic power and electric efficiency, gaining traction among manufacturers seeking balanced performance, productivity, and energy savings.

By Clamping Force

Machines with 0 to 200 tons force account for a considerable portion of demand supported by usage in small component manufacturing, consumer goods, and medical device production. The 201 to 500 tons force segment represents a major share driven by broad applicability in automotive parts, packaging products, and mid sized industrial components. Machines above 500 tons force are expanding steadily due to increasing production of large automotive parts, industrial equipment components, and high volume manufacturing requirements.

By End User

Automotive remains the dominant end user segment supported by extensive use of molded plastic components, lightweight material adoption, and large scale production needs. Consumer goods and packaging industries maintain strong demand driven by mass production of containers, household products, and fast moving consumer goods packaging. Healthcare is growing steadily due to rising demand for precision molded medical devices and sterile components. Electrical and electronics industries contribute significantly through production of connectors, housings, and insulation components, while other end users continue adopting advanced molding technologies to enhance manufacturing efficiency and product quality.

Unlock 360° Market Intelligence with DataM Subscription Services: https://www.datamintelligence.com/reports-subscription

Power your decisions with real-time competitor tracking, strategic forecasts, and global investment insights all in one place.

✅ Competitive Landscape

✅ Sustainability Impact Analysis

✅ KOL / Stakeholder Insights

✅ Unmet Needs & Positioning, Pricing & Market Access Snapshots

✅ Market Volatility & Emerging Risks Analysis

✅ Quarterly Industry Report Updated

✅ Live Market & Pricing Trends

✅ Import-Export Data Monitoring

Have a look at our Subscription Dashboard: https://www.youtube.com/watch?v=x5oEiqEqTWg

Contact Us –

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: Sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

About Us –

DataM Intelligence is a Market Research and Consulting firm that provides end-to-end business solutions to organizations from Research to Consulting. We, at DataM Intelligence, leverage our top trademark trends, insights and developments to emancipate swift and astute solutions to clients like you. We encompass a multitude of syndicate reports and customized reports with a robust methodology.

Our research database features countless statistics and in-depth analyses across a wide range of 6300+ reports in 40+ domains creating business solutions for more than 200+ companies across 50+ countries; catering to the key business research needs that influence the growth trajectory of our vast clientele.

This release was published on openPR.